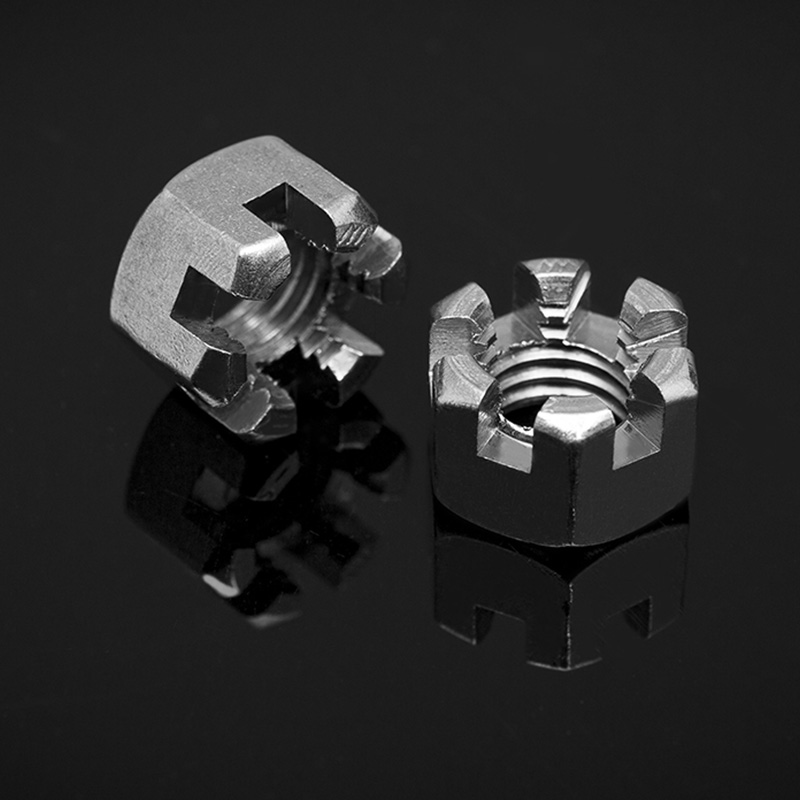

DIN 439 Stainless steel Chamfered hexagon thin nuts

|

Appearance Characteristics |

Shape: Hexagonal with six symmetrical sides, allowing for easy tightening and removal using a wrench or other tools. This design provides better operational convenience in confined spaces. Thickness: Compared to standard hex nuts, it is thinner, classified as a thin nut. It is relatively lightweight and occupies less space. Surface Treatment: Typically retains the natural stainless steel color with a metallic luster. It can also undergo passivation, polishing, or other surface treatments as needed to enhance corrosion resistance and aesthetics. |

|

Internal Features |

Thread: Features internal standard metric threads with high precision, ensuring a good fit with bolts of corresponding specifications for secure and reliable connections. The thread direction is typically right-handed, aligning with common usage habits in most applications. Material Structure: Primarily made of stainless steel, such as 304 or 316, with a uniform internal structure. This ensures even load distribution under force, reducing the risk of localized damage. |

|

Core Purpose |

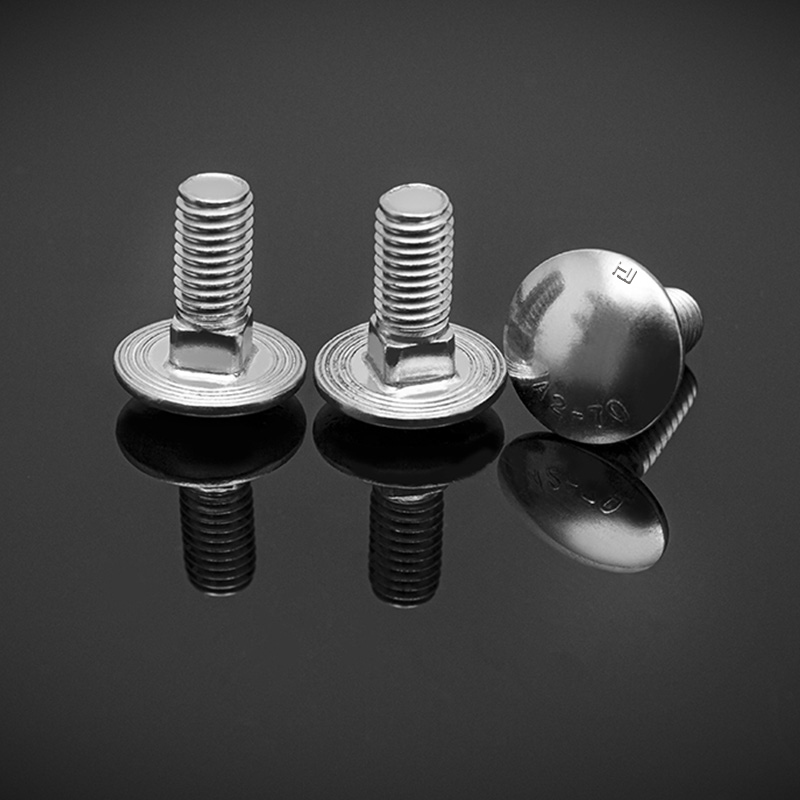

Connection and Fastening: Used to connect two or more parts together, working in conjunction with a bolt to maintain their relative position. This allows for the transmission of force or torque, making it an essential fastening component in mechanical manufacturing, equipment installation, and other fields. |

|

Advantages and Features |

Strong Corrosion Resistance: Made of stainless steel, it offers excellent resistance to corrosion, withstanding exposure to acids, alkalis, and salts. Suitable for humid and corrosive environments, it extends service life and reduces maintenance costs. High Strength: Despite being a thin nut, it still provides sufficient strength to withstand certain loads, meeting fastening requirements for most standard applications. Easy Installation: The hexagonal shape allows for convenient operation with various wrenches, making installation and removal efficient and improving work productivity. Good Versatility: Compliant with the DIN 439-2 standard, ensuring standardized dimensions and compatibility with bolts and parts that meet the same standard. This allows for easy interchangeability in different equipment and projects. |

|

Typical Uses |

Mechanical Manufacturing: Used in the assembly of various mechanical equipment, such as machine tools, engines, and gear reducers, to connect different components and ensure proper operation. Electronics and Electrical Applications: Used in electronic devices, electrical control cabinets, and similar products to secure circuit boards, terminal blocks, and enclosures, ensuring stable and reliable electrical connections. Furniture Industry: Applied in furniture assembly, including tables, chairs, cabinets, and bookshelves, to securely connect different parts while maintaining the aesthetic appearance of the furniture. Construction and Decoration: Used in construction and decoration projects to secure components such as doors, windows, curtain walls, and railings, providing reliable connections and support. |

|

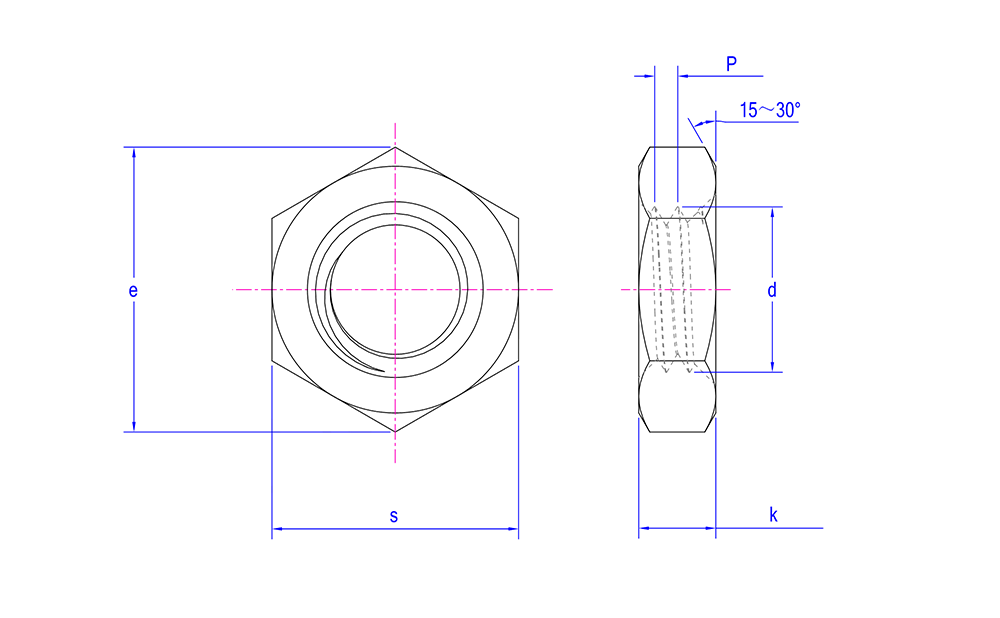

Key Indicators for Selection |

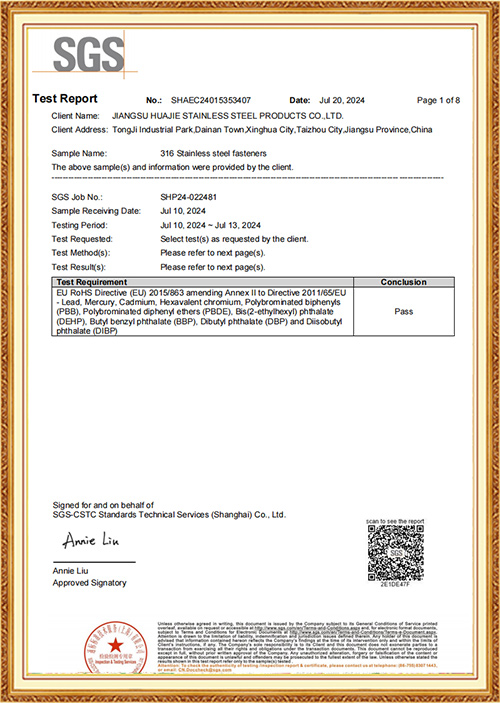

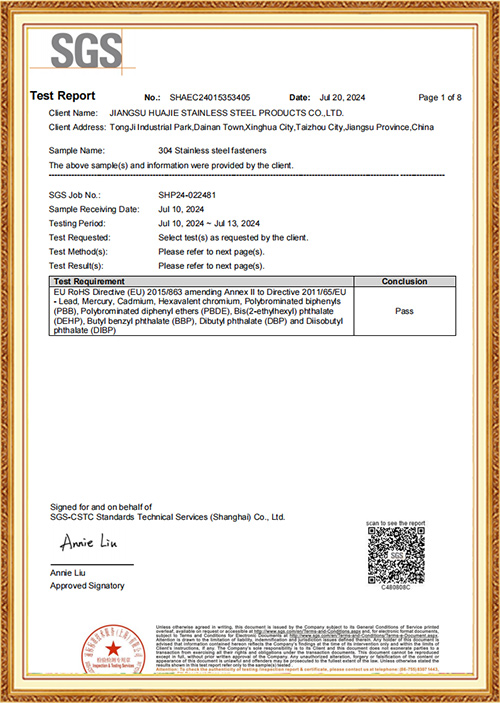

Size Specifications: Includes thread diameter, pitch, nut outer diameter, and thickness. The appropriate specification should be selected based on the bolt size and the requirements of the connected components to ensure precise fitting. Material: Choose the appropriate stainless steel material based on the usage environment and requirements for corrosion resistance and strength. For example, 304 stainless steel is suitable for general corrosive environments, while 316 stainless steel offers better resistance to strong acids and alkalis in harsher conditions. Strength Grade: Different applications require different nut strength levels. The appropriate strength grade should be selected based on the actual load conditions to ensure connection safety. |

|

Industry-Specific Requirements |

Aerospace Industry: Requires extremely high standards for nut quality and performance, meeting strict aerospace regulations regarding material purity, strength, and fatigue resistance. Special surface treatments and rigorous quality inspections are often necessary to ensure flight safety. Automotive Industry: Nuts must have excellent vibration resistance and reliability to withstand the shocks and vibrations during vehicle operation. They must also comply with specific automotive manufacturer standards, including appearance quality and rust prevention. Food and Beverage Industry: Since food safety is a priority, nuts must be made of non-toxic, non-contaminating stainless steel with a smooth surface to prevent bacterial growth. They must also meet relevant food hygiene standards. |

English

English русский

русский Deutsch

Deutsch عربى

عربى