Understanding 316 Stainless Steel Threaded Rods 316 stainless steel threaded rods are highly versatile fasteners known for their exceptional corrosion resistanc...

READ MORE

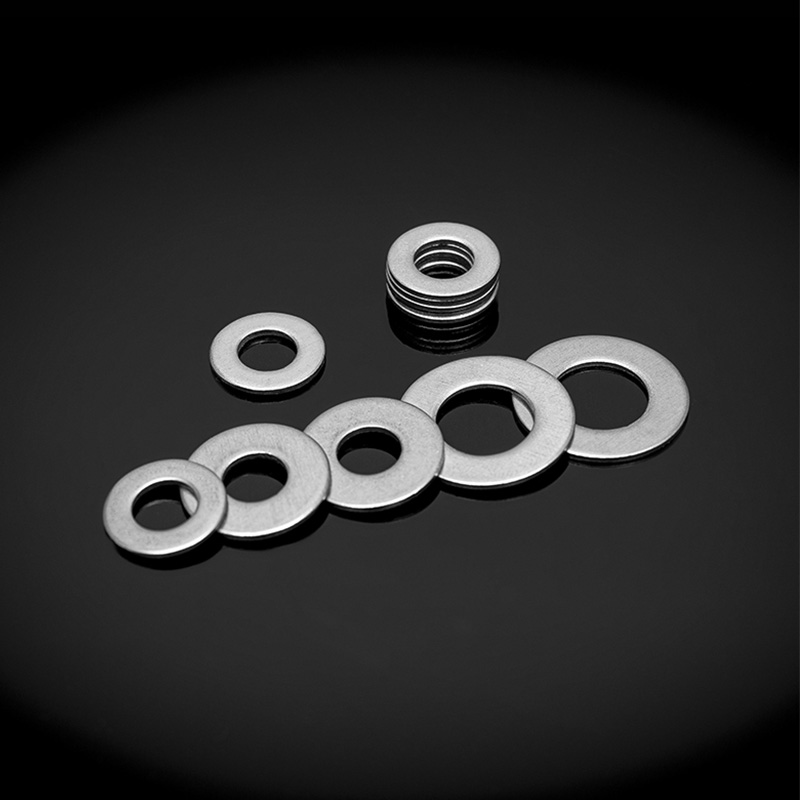

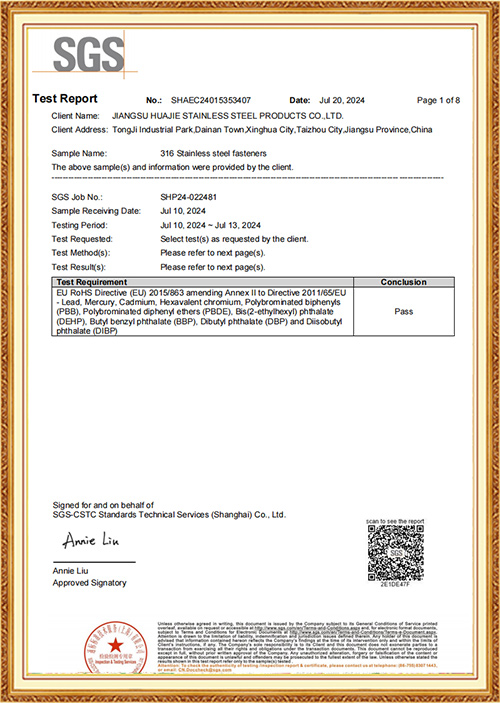

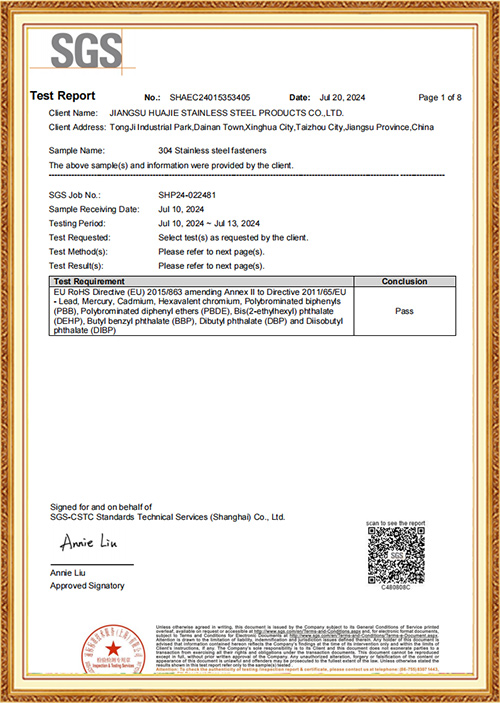

We are Wholesale Stainless Steel Washers Manufacturers and Stainless Steel Washers Factory in China, our company mainly produces stainless steel fasteners, The company has domestic and foreign advanced production and testing equipment, and product standards Cover GB/JIS/DIN/ANSI/ISO standards, The material includes 201/304/316L, etc. The products are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemical, military equipment, aerospace, and other fields.

-

-

Introduction to Hex Nuts Hex nuts are one of the most common fasteners used in machinery, construction, and various industrial applications. They are designed t...

READ MORE -

Structural Design Features of Mushroom Head Square Neck Bolts Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and...

READ MORE -

Introduction to High-Strength Stainless Steel Screws High-strength stainless steel screws are essential fasteners for applications that demand durability, corro...

READ MORE

Choosing the Right Material for Washers: A Practical Guide to Stainless Steel Washers and Beyond for Reliable Industrial Performance

Selecting the appropriate material for washers is a crucial decision that directly impacts the longevity, safety, and efficiency of any bolted assembly. Among the various options, stainless steel washers have become increasingly popular due to their excellent corrosion resistance and robust mechanical properties. However, understanding how stainless steel compares to other common materials like carbon steel, brass, or even non-metallic washers can help businesses make smarter purchasing choices that align with specific application needs.

Stainless steel washers offer a unique combination of durability and resistance to environmental factors, making them ideal for use in both indoor and outdoor settings where moisture or chemicals might otherwise cause rapid corrosion. Unlike ordinary carbon steel washers, which may require additional coatings or treatments to withstand rust, stainless steel washers naturally form a protective oxide layer that guards against oxidation. This inherent property reduces maintenance demands and extends the service life of the fastened joint, which is why many manufacturers and suppliers recommend them for critical applications in construction, marine, and chemical processing industries.

On the other hand, carbon steel washers are often favored for their strength and affordability, particularly in applications where exposure to harsh conditions is minimal or where surface protection can be enhanced with zinc plating or other finishes. While carbon steel washers excel in load-bearing capacity, their vulnerability to corrosion without treatment limits their use in environments prone to moisture or chemical exposure. Brass washers, although less common, offer excellent electrical conductivity and are often selected in electrical or decorative applications. They also provide moderate corrosion resistance but come at a higher price point and lower mechanical strength compared to steel variants.

Non-metallic washers, made from materials like nylon or PTFE, present a distinct set of advantages such as electrical insulation, chemical inertness, and vibration dampening. While these washers are invaluable in certain specialized fields, their lower mechanical strength and heat resistance restrict their suitability for heavy-duty fastening tasks. For this reason, manufacturers supplying stainless steel washers and other metal washers often emphasize selecting the right washer material as a key step in preventing premature joint failure and costly downtime.

Another important consideration is the compatibility between washers and mating fasteners. Using stainless steel washers with bolts or nuts made of different materials can lead to galvanic corrosion if not carefully managed. Our industry experience shows that matching or closely compatible metals ensures optimal joint integrity and reduces maintenance frequency. As a trusted manufacturer and exporter of high-quality stainless steel washers, we advise customers to evaluate the entire fastening system holistically, taking into account factors such as load, environment, and mechanical stresses.

Investing in premium washers made from appropriate materials like stainless steel not only safeguards the performance of the assembly but also contributes to overall cost efficiency by minimizing replacements and repairs. With advancements in manufacturing processes, our range of stainless steel washers delivers consistent dimensional accuracy and reliable mechanical properties, ensuring seamless integration with your fasteners. By choosing washers tailored to your specific industrial demands, you’re not just buying a component—you’re securing peace of mind for your projects.

Understanding the nuanced differences between stainless steel washers and alternative materials empowers businesses to optimize their fastening solutions. Whether corrosion resistance, strength, electrical insulation, or cost-effectiveness is the priority, selecting the right washer material plays an indispensable role in sustaining the durability and functionality of bolted joints. For professional advice or customized solutions, our manufacturing expertise is at your service to help you achieve the best results in your applications.

English

English русский

русский Deutsch

Deutsch عربى

عربى