Understanding 316 Stainless Steel Threaded Rods 316 stainless steel threaded rods are highly versatile fasteners known for their exceptional corrosion resistanc...

READ MORE

We are Wholesale Stainless Steel Lock Nut Suppliers and Stainless Steel Lock Nut Company in China, our company mainly produces stainless steel fasteners, The company has domestic and foreign advanced production and testing equipment, and product standards Cover GB/JIS/DIN/ANSI/ISO standards, The material includes 201/304/316L, etc. The products are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemical, military equipment, aerospace, and other fields.

-

-

Introduction to Hex Nuts Hex nuts are one of the most common fasteners used in machinery, construction, and various industrial applications. They are designed t...

READ MORE -

Structural Design Features of Mushroom Head Square Neck Bolts Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and...

READ MORE -

Introduction to High-Strength Stainless Steel Screws High-strength stainless steel screws are essential fasteners for applications that demand durability, corro...

READ MORE

Exploring the Anti-Loosening Features of Stainless Steel Lock Nuts

Stainless steel lock nuts are essential fastening components designed to resist loosening caused by vibration, impact, or torque variations. Their anti-loosening functionality comes from structural enhancements such as integrated nylon inserts or specially shaped metal locking elements. These design features increase the friction or create a mechanical lock between the nut and bolt, effectively preventing movement under dynamic loads.

The reliability of stainless steel lock nuts makes them especially valuable in applications where safety and long-term stability are critical. In the railway industry, for example, lock nuts are used to secure rail tracks that are subject to constant vibration and shifting loads from high-speed trains. In the aerospace sector, they are used to fasten key components such as aircraft wings and landing gear—areas where even the smallest amount of loosening can compromise structural integrity.

One common variant is the nylon-insert lock nut, often produced through a rigorous multi-step process. It begins with cold forging and cold extrusion of tempered stainless steel using a forming machine. The threads are then precision-machined by a tapping machine. Finally, a nylon ring is mechanically pressed into the nut body using a capping machine, completing a fastening solution that can resist loosening through both friction and deformation locking.

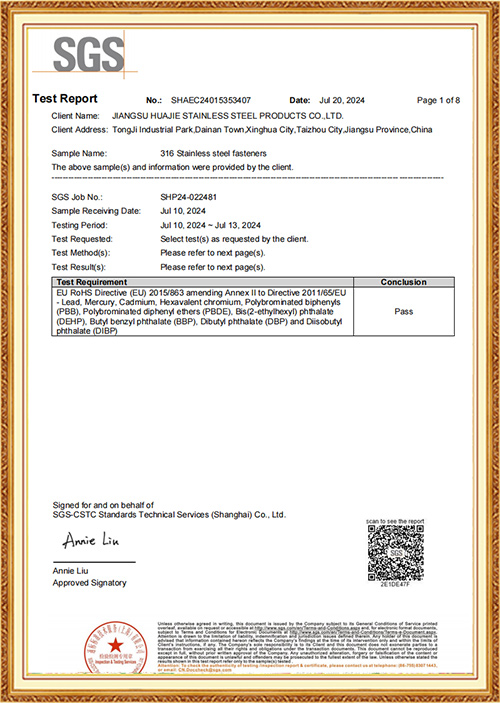

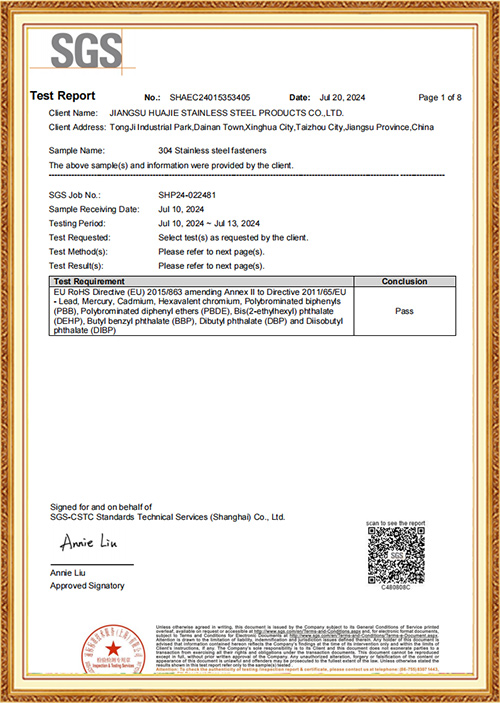

Jiangsu Huajie Stainless Steel Products Co., Ltd., founded in 2003, has built a solid reputation as one of China’s leading manufacturers of stainless steel fasteners, including high-performance lock nuts. The company operates a factory that spans 80,000 square meters and maintains an annual production capacity of 60,000 tons. With more than two decades of development, Huajie continues to innovate and deliver fastening solutions that meet the demands of modern industry.

Huajie’s stainless steel lock nuts are produced using advanced domestic and international manufacturing equipment. The company adheres to multiple standards, including GB, JIS, DIN, ANSI, and ISO. Materials such as 201, 304, and 316L stainless steel are commonly used to meet various performance and corrosion-resistance requirements. These products find broad applications in sectors such as nuclear power, mechanical equipment, new energy, petrochemical, military, telecommunications, and aerospace.

In addition to its robust production capabilities, Jiangsu Huajie has achieved ISO9001, ISO14001, and ISO18001 certifications, along with AAA-grade standard compliance in business conduct. The company’s R&D strengths are backed by its Jiangsu enterprise technology center and the Taizhou engineering technology research center. Collaborations with institutions like Jiangsu University further strengthen Huajie’s position as a technology-driven enterprise with a focus on product quality and innovation.

The effectiveness of stainless steel lock nuts, especially when precision-manufactured and certified to global standards, plays a critical role in enhancing safety across a wide range of industries. As technology and infrastructure demands grow, the need for high-quality, anti-loosening fasteners continues to rise. Through decades of experience, continuous improvement, and a strong focus on customer satisfaction, Jiangsu Huajie is committed to supplying the fasteners that keep modern systems secure.

With "Quality First, Customers First" as its guiding principle, Jiangsu Huajie welcomes global partners to explore collaboration opportunities. From aerospace to renewable energy, stainless steel lock nuts manufactured by Huajie help ensure that vital connections remain strong, reliable, and secure—no matter how challenging the environment.

English

English русский

русский Deutsch

Deutsch عربى

عربى