Understanding 316 Stainless Steel Threaded Rods 316 stainless steel threaded rods are highly versatile fasteners known for their exceptional corrosion resistanc...

READ MORE

We are Wholesale Stainless Steel Spring Washers Suppliers and Stainless Steel Spring Washers Company in China, our company mainly produces stainless steel fasteners, The company has domestic and foreign advanced production and testing equipment, and product standards Cover GB/JIS/DIN/ANSI/ISO standards, The material includes 201/304/316L, etc. The products are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemical, military equipment, aerospace, and other fields.

-

-

Introduction to Hex Nuts Hex nuts are one of the most common fasteners used in machinery, construction, and various industrial applications. They are designed t...

READ MORE -

Structural Design Features of Mushroom Head Square Neck Bolts Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and...

READ MORE -

Introduction to High-Strength Stainless Steel Screws High-strength stainless steel screws are essential fasteners for applications that demand durability, corro...

READ MORE

The Technical Advantages of Using Stainless Steel Spring Washers in Modern Equipment

In many modern mechanical and industrial applications, fastening components face constant challenges due to vibration, temperature fluctuations, and load variations. One small but crucial element that plays a significant role in maintaining fastening stability is the spring washer. Among the various types available, stainless steel spring washers stand out for their durability, anti-loosening performance, and adaptability in demanding environments.

Spring washers, though annular in shape, differ from ordinary washers by their unique spiral form with a cutout that allows for elastic deformation under pressure. This spiral design provides a gap in its free state, which compresses when subjected to an external force, effectively creating tension that resists loosening of bolts and screws. This feature is particularly valuable in equipment exposed to constant vibrations or shifting loads, where fasteners are at risk of working themselves loose over time.

One of the primary technical advantages of stainless steel spring washers is their elastic recovery property. When installed, the washer is slightly compressed, which generates a counteracting force that keeps the joint tight. This mechanical tension helps to maintain the integrity of bolted joints, especially in high-vibration environments such as automobile engines. In such applications, stainless steel spring washers are frequently used in connections involving crankshafts, connecting rods, and other components that experience cyclical stress.

Stainless steel, particularly grades like 304 and 316L, enhances the performance of spring washers by offering excellent corrosion resistance, even in harsh environments. This makes them ideal for outdoor equipment, chemical processing machinery, and marine applications where moisture and corrosive agents are present. Stainless steel’s high strength-to-weight ratio and ability to withstand oxidation ensure that spring washers maintain their shape and performance over time.

In addition to automotive applications, these washers are also widely used in the aerospace industry, where components such as landing gear assemblies demand a high degree of reliability and secure fastening. Vibrations experienced during takeoff and landing could compromise mechanical joints without the help of spring washers. Their resilience and mechanical stability make them essential for systems where human safety is a key concern.

Another area that benefits from stainless steel spring washers is the electronics and electrical industries. Within these sectors, vibration from operating machinery can loosen electrical contacts, potentially causing signal loss or short circuits. Spring washers help maintain consistent contact pressure in electrical housings and circuit board mountings, contributing to the long-term reliability of electronic devices.

Behind the consistent quality of stainless steel spring washers lies a complex and carefully controlled manufacturing process. These washers are usually made from high-quality spring steel and undergo heat treatment processes such as rolling, quenching, and tempering. Quenching enhances hardness, while tempering reduces internal stress and improves the washer’s elasticity and toughness. This combination ensures that the washers can absorb and recover from repeated load cycles without permanent deformation.

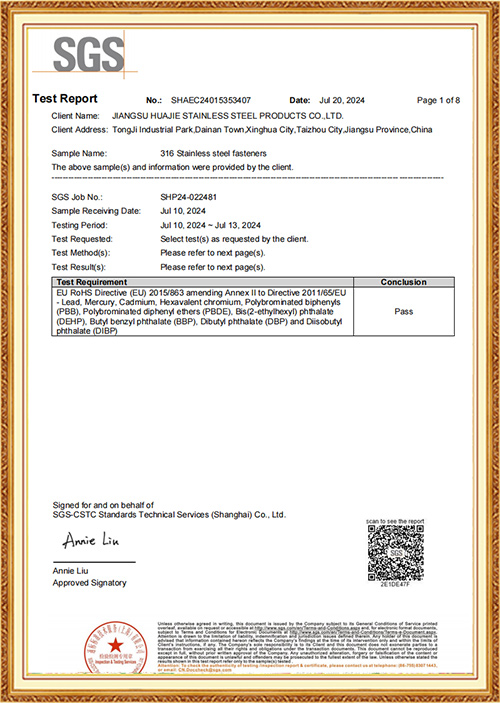

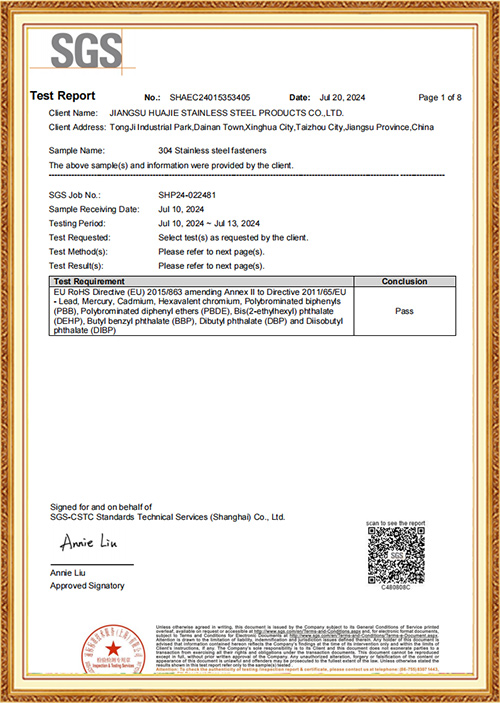

As a recognized leader in stainless steel fastener manufacturing, Jiangsu Huajie Stainless Steel Products Co., Ltd. brings over 20 years of expertise in producing precision-engineered components, including spring washers. Established in 2003 with a registered capital of 18 million RMB, the company operates a state-of-the-art production facility spanning 80,000 square meters and boasting an annual output of 60,000 tons.

Jiangsu Huajie’s products conform to global standards including GB, JIS, DIN, ANSI, and ISO, and utilize premium materials such as 201, 304, and 316L stainless steel. The company’s production and testing equipment meet both domestic and international benchmarks, enabling it to serve industries as diverse as high-speed rail, nuclear power, telecommunications, new energy, petrochemicals, military, and aerospace.

Certified under ISO 9001, ISO 14001, and ISO 18001, Jiangsu Huajie also holds AAA-level enterprise credit ratings and has been awarded multiple recognitions for innovation and high-tech manufacturing. It operates in collaboration with academic institutions like Jiangsu University and maintains provincial-level technology centers, ensuring continuous development of advanced fastener technologies.

"Quality First, Customers First" is the guiding principle of Jiangsu Huajie. By integrating stringent quality control, innovative engineering, and customer-oriented service, the company is committed to providing reliable stainless steel fasteners that meet the demands of today’s evolving industries. Whether for automotive engines, aerospace components, or precision electronics, stainless steel spring washers from Jiangsu Huajie offer a combination of mechanical strength, elasticity, and corrosion resistance that makes them indispensable in modern equipment.

Stainless steel spring washers deliver technical advantages that go beyond simple fastener support—they are essential in ensuring the long-term stability and safety of mechanical joints in a wide range of high-performance applications. With manufacturers like Jiangsu Huajie leading the way, the future of fastening technology continues to evolve with precision and reliability at its core.

English

English русский

русский Deutsch

Deutsch عربى

عربى