Understanding 316 Stainless Steel Threaded Rods 316 stainless steel threaded rods are highly versatile fasteners known for their exceptional corrosion resistanc...

READ MORE

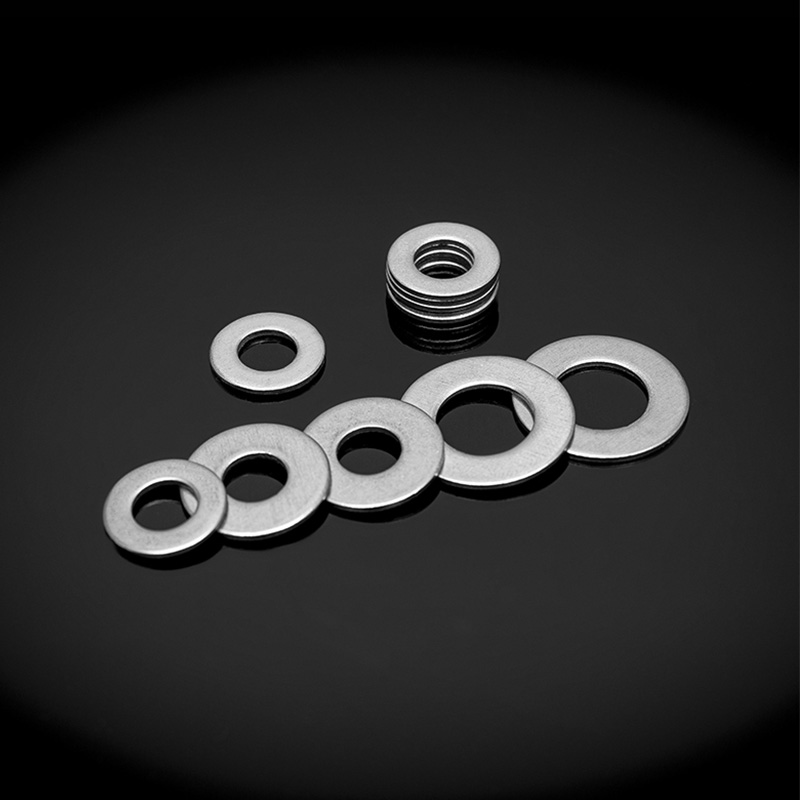

We are Wholesale Stainless Steel Flat Washers Suppliers and Stainless Steel Flat Washers Company in China, our company mainly produces stainless steel fasteners, The company has domestic and foreign advanced production and testing equipment, and product standards Cover GB/JIS/DIN/ANSI/ISO standards, The material includes 201/304/316L, etc. The products are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemical, military equipment, aerospace, and other fields.

-

-

Introduction to Hex Nuts Hex nuts are one of the most common fasteners used in machinery, construction, and various industrial applications. They are designed t...

READ MORE -

Structural Design Features of Mushroom Head Square Neck Bolts Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and...

READ MORE -

Introduction to High-Strength Stainless Steel Screws High-strength stainless steel screws are essential fasteners for applications that demand durability, corro...

READ MORE

Choosing the Right Stainless Steel Flat Washer for Your Assembly

When it comes to mechanical assemblies that rely on bolted or screwed connections, a small yet crucial component often determines the overall stability—the flat washer. A stainless steel flat washer is a flat, annular disk with a hole in the center. Its structure is simple: both sides are flat, the outer and inner diameters are precisely defined, and the thickness is uniformly distributed. While it may appear basic in form, its role in fastening systems is vital—primarily distributing load, reducing surface wear, and preventing loosening under vibration.

Choosing the right stainless steel flat washer involves considering several key factors: material, thickness, inner and outer diameter, and compatibility with the bolt or nut used. Common flat washers typically range from 0.5 mm to 5 mm in thickness, with dimensions tailored to the specifications of the corresponding fasteners. Selecting a washer that fits accurately ensures proper load distribution and a secure connection, especially in applications where structural integrity and safety are critical.

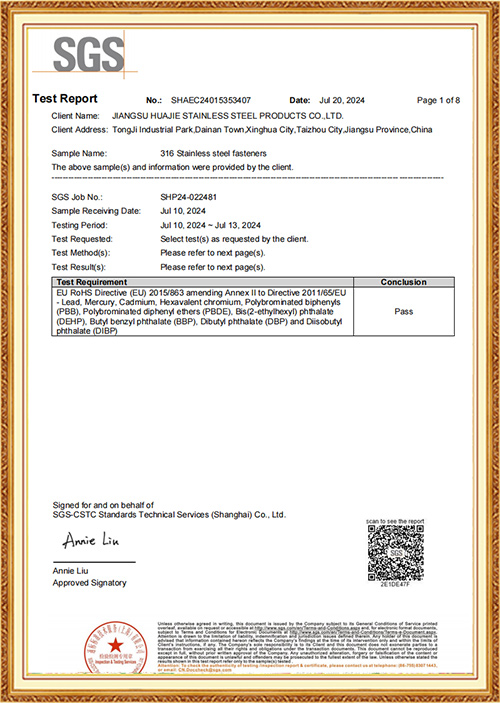

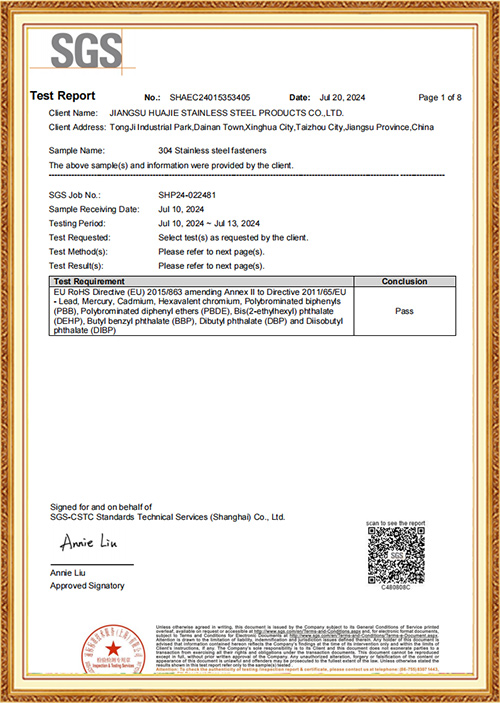

Material selection is another important aspect. Stainless steel, known for its corrosion resistance and strength, is an ideal material for flat washers used in harsh environments or applications requiring long-term reliability. Grades such as 201, 304, and 316L are often used depending on the exposure to moisture, chemicals, or extreme temperatures. Among them, 316L offers the highest corrosion resistance, making it suitable for marine or chemical processing industries.

Huajie’s washers are manufactured in accordance with GB, JIS, DIN, ANSI, and ISO standards, ensuring compatibility across a range of international applications. Their products are used in industries such as high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemicals, military equipment, and aerospace. This broad application range reflects both the versatility of the stainless steel flat washer and the engineering reliability that Huajie integrates into each component.

Beyond production capabilities, Jiangsu Huajie places a strong emphasis on quality assurance and innovation. The company has obtained certifications including ISO 9001, ISO 14001, and ISO 18001, and has earned the AAA-level enterprise credit rating. Its testing processes comply with global standards, further confirmed by recognized compliance measurement certificates. Huajie also owns provincial and municipal research centers—Jiangsu Enterprise Technology Center and Taizhou Engineering Technology Research Center—and has received recognition for its contributions to new technology and product development in stainless steel fasteners.

The commitment to precision and quality extends through Huajie’s partnerships with universities such as Jiangsu University, focusing on the development of stainless steel fasteners that meet evolving industry needs. The company continues to advance the technical level of its washers, ensuring that each piece—no matter how small—is manufactured with the same rigor as any major structural component.

Selecting the right stainless steel flat washer goes beyond picking a piece of metal with a hole in it. It’s about ensuring proper fit, material compatibility, and performance under specific operating conditions. Whether you're assembling a piece of industrial machinery or installing components in a high-performance vehicle, a well-chosen flat washer contributes to the overall durability and functionality of your product.

For those seeking dependable stainless steel flat washers manufactured to global standards, Jiangsu Huajie remains a trusted supplier. With two decades of experience and a customer-first philosophy, Huajie welcomes collaboration with businesses around the world. Together, let’s build stronger, more reliable assemblies—one flat washer at a time.

English

English русский

русский Deutsch

Deutsch عربى

عربى