Understanding 316 Stainless Steel Threaded Rods 316 stainless steel threaded rods are highly versatile fasteners known for their exceptional corrosion resistanc...

READ MORE

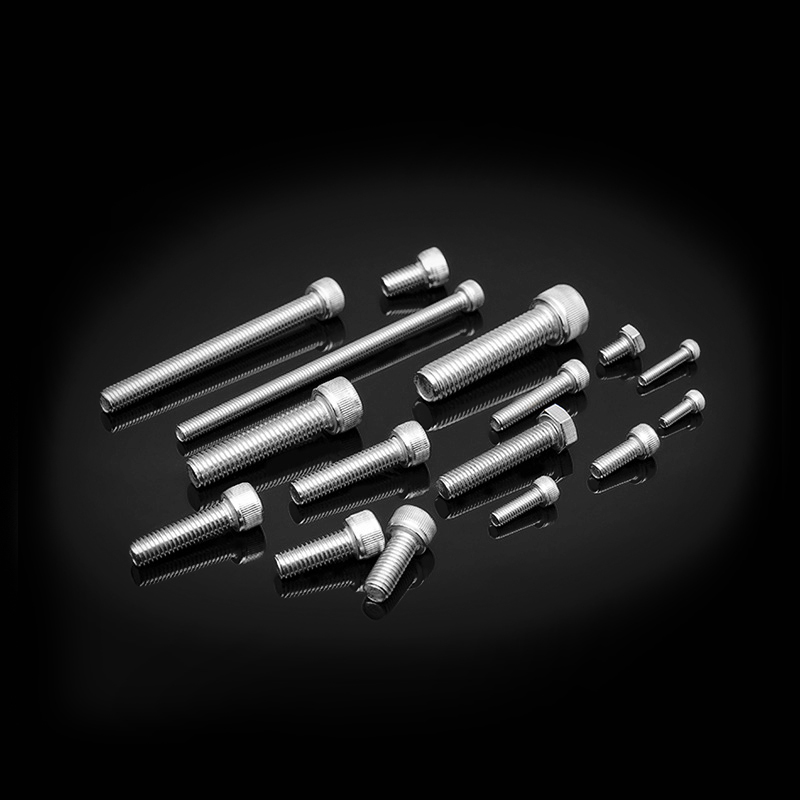

We are Wholesale Hexagon Socket Head Cap Screws Suppliers and Hexagon Socket Head Cap Screws Company in China, our company mainly produces stainless steel fasteners, The company has domestic and foreign advanced production and testing equipment, and product standards Cover GB/JIS/DIN/ANSI/ISO standards, The material includes 201/304/316L, etc. The products are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemical, military equipment, aerospace, and other fields.

-

-

Introduction to Hex Nuts Hex nuts are one of the most common fasteners used in machinery, construction, and various industrial applications. They are designed t...

READ MORE -

Structural Design Features of Mushroom Head Square Neck Bolts Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and...

READ MORE -

Introduction to High-Strength Stainless Steel Screws High-strength stainless steel screws are essential fasteners for applications that demand durability, corro...

READ MORE

Hexagon Socket Head Cap Screws Installation Method and Its Effect on Connection Performance

In the field of mechanical engineering, fasteners play a critical role in ensuring structural integrity and performance. Among various types of fasteners, hexagon socket head cap screws are widely used due to their high strength, compact design, and ease of installation. As one of the leading stainless steel fastener manufacturers in China, Jiangsu Huajie Stainless Steel Products Co., Ltd. has been committed to producing high-quality fasteners for over 20 years, offering products that meet international standards such as GB, JIS, DIN, ANSI, and ISO. With an annual production capacity of 60,000 tons and a factory area covering 80,000 square meters, Jiangsu Huajie provides reliable solutions for industries including high-speed rail, nuclear power, new energy, aerospace, and more.

This article explores the installation methods of hexagon socket head cap screws and how these methods impact connection performance , especially when using high-quality materials like stainless steel grades 304 and 316L—materials that Jiangsu Huajie specializes in.

1. Overview of Hexagon Socket Head Cap Screws

Hexagon socket head cap screws feature a cylindrical head with a hexagonal socket drive. These screws are typically installed using an Allen wrench or hex key, allowing for high torque transmission without damaging the screw head. Their design enables them to be used in tight spaces where traditional slotted or Phillips-head screws may not fit.

These screws are commonly made from carbon steel, alloy steel, or stainless steel. At Jiangsu Huajie, we focus on manufacturing stainless steel versions—particularly A2-70 (SUS304) and A4-80 (SUS316L) —which offer superior corrosion resistance and mechanical properties, making them ideal for harsh environments.

2. Installation Methods for Hexagon Socket Head Cap Screws

Proper installation is crucial to achieving optimal connection performance. The following methods are commonly employed:

2.1 Torque-Controlled Tightening

Torque-controlled tightening involves applying a specific amount of rotational force (torque) to the screw to achieve the desired clamping load. This method requires the use of calibrated torque wrenches or screwdrivers.

At Jiangsu Huajie, our technical team works closely with clients to recommend appropriate torque values based on material type, screw size, and application environment. Using the correct torque ensures that the screw achieves sufficient preload without risking thread stripping or screw failure.

2.2 Angle-Controlled Tightening

Angle-controlled tightening involves rotating the screw a specific number of degrees after initial contact with the mating surface. This method is particularly useful when dealing with materials that have variable friction coefficients, such as stainless steel.

By combining angle and torque control (known as torque-angle method), installers can achieve consistent preload even under fluctuating conditions. This technique is often used in precision applications such as aerospace and automotive assembly lines.

2.3 Lubrication Application

Friction plays a significant role in screw tightening. Applying lubricant to the threads reduces friction and allows for more accurate torque application. However, it also increases the risk of over-tightening if torque values are not adjusted accordingly.

Jiangsu Huajie recommends using anti-seize compounds or molybdenum-based lubricants when installing stainless steel screws to prevent galling—a common issue with stainless steel fasteners due to cold welding during installation.

2.4 Sequential Tightening Pattern

For multi-fastener connections (e.g., flange joints), it's essential to follow a sequential tightening pattern, such as a star or crisscross pattern. This ensures even load distribution across all fasteners and prevents uneven stress concentration.

Our engineers at Jiangsu Huajie provide detailed installation guides and recommendations tailored to each client’s specific application, helping ensure long-term reliability and safety.

3. Impact of Installation Method on Connection Performance

The effectiveness of a bolted joint depends heavily on the installation process. Improper installation can lead to several issues, including:

Under-tightening : Leads to insufficient clamping force, increasing the risk of loosening due to vibration or thermal expansion.

Over-tightening : Causes plastic deformation, thread damage, or even fracture of the screw.

Uneven Load Distribution : Results in premature fatigue failure and reduced service life.

Using the proper installation method enhances the preload of the screw, which directly affects the joint’s ability to resist external forces. A well-installed hexagon socket head cap screw can maintain its integrity even under dynamic loads, extreme temperatures, or corrosive environments—conditions commonly encountered in industries served by Jiangsu Huajie.

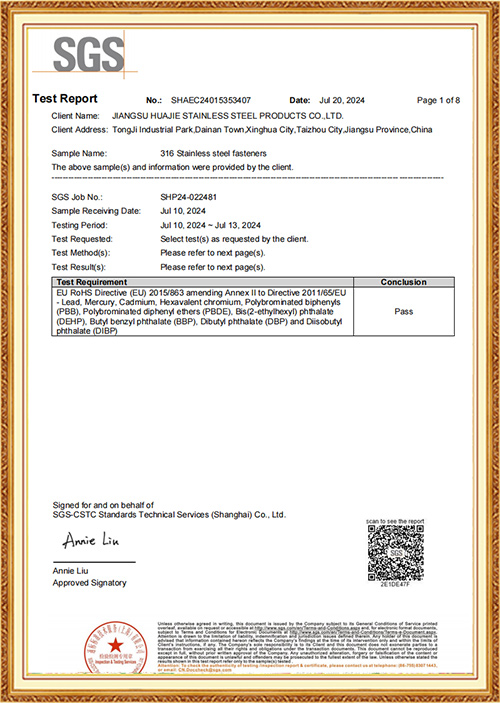

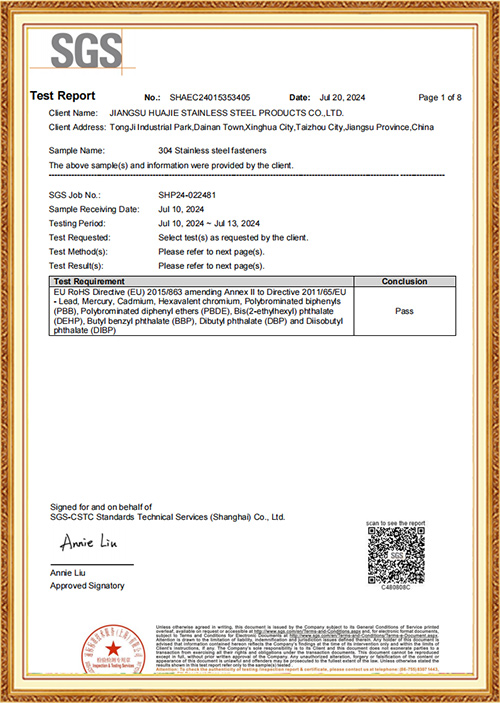

4. Quality Assurance and Innovation at Jiangsu Huajie

As a certified manufacturer under the ISO 9001/14001/18001 management systems , Jiangsu Huajie ensures that every product—from raw material selection to final inspection—meets the highest quality standards. Our advanced testing equipment includes tensile testers, hardness testers, salt spray corrosion chambers, and more, enabling us to verify both mechanical and environmental performance.

We have established close partnerships with universities such as Jiangsu University , focusing on R&D efforts to improve the performance of stainless steel fasteners. Our company has been recognized as a National High-Tech Enterprise and has received recognition for new technologies and products from the Jiangsu provincial government.

Hexagon socket head cap screws are indispensable components in modern engineering, especially in high-performance and safety-critical applications. Proper installation techniques—such as controlled torque, angle tightening, lubrication, and sequential patterns—are vital to achieving reliable and durable connections.

At Jiangsu Huajie Stainless Steel Products Co., Ltd. , we take pride in delivering top-tier fasteners that not only meet but exceed international standards. Our commitment to innovation, quality assurance, and customer support makes us a trusted partner for industries demanding excellence in fastening solutions.

Whether you're working on aerospace components, offshore platforms, or renewable energy installations, choosing the right fastener and following the correct installation procedure can make all the difference in ensuring long-term performance and safety.

English

English русский

русский Deutsch

Deutsch عربى

عربى