Understanding 316 Stainless Steel Threaded Rods 316 stainless steel threaded rods are highly versatile fasteners known for their exceptional corrosion resistanc...

READ MORE

We are Wholesale Stainless Steel Square Nut Suppliers and Stainless Steel Square Nut Company in China, our company mainly produces stainless steel fasteners, The company has domestic and foreign advanced production and testing equipment, and product standards Cover GB/JIS/DIN/ANSI/ISO standards, The material includes 201/304/316L, etc. The products are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemical, military equipment, aerospace, and other fields.

-

-

Introduction to Hex Nuts Hex nuts are one of the most common fasteners used in machinery, construction, and various industrial applications. They are designed t...

READ MORE -

Structural Design Features of Mushroom Head Square Neck Bolts Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and...

READ MORE -

Introduction to High-Strength Stainless Steel Screws High-strength stainless steel screws are essential fasteners for applications that demand durability, corro...

READ MORE

Comparing Square and Hex Nuts: Which Works Better in Narrow Spaces

When selecting fasteners for different engineering or mechanical tasks, the shape and function of a nut can make a substantial difference in installation efficiency and long-term performance. Two common nut types—square nuts and hex nuts—are often compared, particularly in applications where space constraints or specialized tools are involved. While hex nuts are widely used across industries due to their versatility and ease of use, square nuts offer distinct advantages in specific situations, especially in confined spaces.

Square nuts, as the name suggests, feature a four-sided shape with prominent corners and flat edges. This geometry can provide better grip for certain types of wrenches or clamps, especially when installation occurs in narrow or recessed areas. In these conditions, the simpler geometry of square nuts allows for easier alignment and engagement with the tool, particularly when the operating angle is restricted. In contrast, hexagonal nuts—despite being more prevalent—may be harder to maneuver in tight spaces due to their need for more rotational clearance.

Although square nuts are not as commonly used as their hexagonal counterparts, they are particularly valuable in older machinery, vintage equipment, or compact assembly designs. For instance, in antique tools or hand-crafted mechanical parts, square nuts can fit more effectively into small cavities and be tightened without requiring wide wrench arcs. Their limited angle of rotation becomes an asset in these specialized contexts, where access is limited and precision matters.

The manufacturing process for square nuts involves several steps that ensure strength, durability, and dimensional accuracy. Typically, the raw stainless steel is shaped into blanks using cold heading or hot forging methods. This is followed by punching and tapping to form internal threads that meet strict specifications. For applications where higher precision is needed, grinding and additional finishing treatments are applied to achieve optimal surface quality and thread alignment.

As one of China’s leading stainless steel fastener manufacturers, Jiangsu Huajie Stainless Steel Products Co., Ltd. plays a significant role in the production of square nuts for both standard and specialized applications. Founded in 2003, Huajie operates with a registered capital of 18 million RMB and covers a production area of 80,000 square meters. The company has grown into a modern manufacturing powerhouse with an annual output capacity of 60,000 tons of stainless steel fasteners.

Huajie offers stainless steel fasteners that conform to multiple international and domestic standards, including GB, JIS, DIN, ANSI, and ISO. The company uses materials such as 201, 304, and 316L stainless steel, ensuring that their products can withstand demanding environments found in high-speed rail, nuclear power, communications, petrochemical, military, and aerospace applications. This material diversity also makes their square nuts suitable for both industrial and artisanal uses, especially when corrosion resistance and longevity are key concerns.

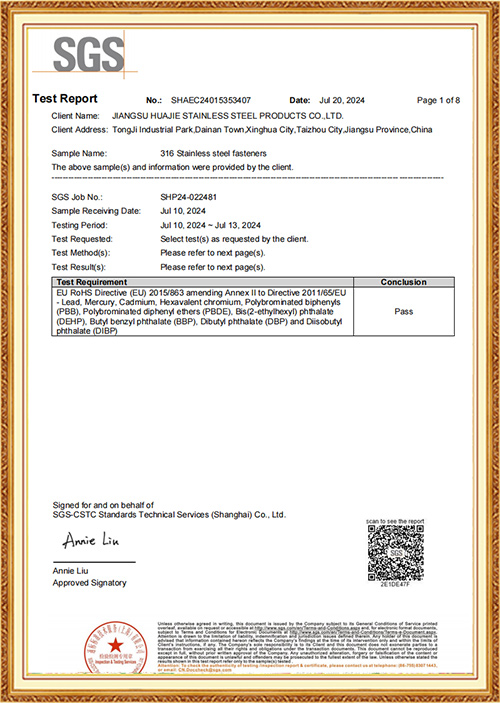

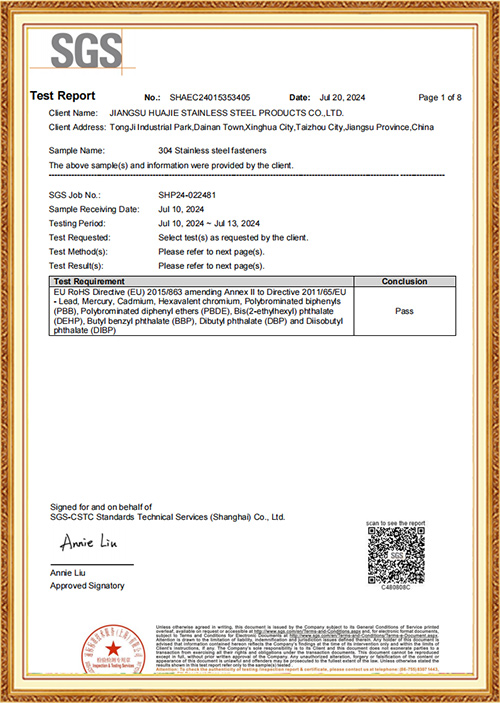

The company’s commitment to quality is reflected in its certifications—Huajie has passed ISO 9001, 14001, and 18001 quality, environmental, and occupational health management systems. It has also received AAA-level business conduct accreditation and holds certifications for compliance and measurement standards. Furthermore, Huajie has established partnerships with institutions like Jiangsu University to drive innovation in stainless steel fastener production, underscoring its technical strength and research capabilities.

Square nuts, while less prominent in everyday fastener inventories, continue to fulfill an important niche. In comparison to hex nuts, their effectiveness in tight or oddly shaped spaces is clear. While hex nuts are easier to engage from multiple angles and are more broadly applicable across industries, square nuts remain a preferred choice when tool compatibility and spatial limitations are central to the assembly task.

Huajie’s expertise in manufacturing stainless steel square nuts ensures that customers can rely on quality and precision, even for specialized orders. With a solid foundation built on two decades of industry experience, state-of-the-art equipment, and a forward-looking R&D approach, Jiangsu Huajie Stainless Steel Products Co., Ltd. is well-positioned to support the evolving needs of global fastener markets.

As the industry continues to advance, the balance between versatility and specialization in fastener selection becomes increasingly important. For professionals facing spatial limitations in design or assembly, stainless steel square nuts—especially those manufactured with care and precision—offer a practical and reliable solution.

English

English русский

русский Deutsch

Deutsch عربى

عربى