Understanding 316 Stainless Steel Threaded Rods 316 stainless steel threaded rods are highly versatile fasteners known for their exceptional corrosion resistanc...

READ MORE

We are Wholesale Stainless Steel Special-Shaped Bolts Suppliers and Stainless Steel Special-Shaped Bolts Company in China, our company mainly produces stainless steel fasteners, The company has domestic and foreign advanced production and testing equipment, and product standards Cover GB/JIS/DIN/ANSI/ISO standards, The material includes 201/304/316L, etc. The products are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemical, military equipment, aerospace, and other fields.

-

-

Introduction to Hex Nuts Hex nuts are one of the most common fasteners used in machinery, construction, and various industrial applications. They are designed t...

READ MORE -

Structural Design Features of Mushroom Head Square Neck Bolts Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and...

READ MORE -

Introduction to High-Strength Stainless Steel Screws High-strength stainless steel screws are essential fasteners for applications that demand durability, corro...

READ MORE

Application performance of Stainless Steel Special-Shaped Bolts in automotive parts fastening systems

Fasteners are essential components in automotive manufacturing, serving as the critical link between various mechanical parts. As vehicle performance requirements continue to rise, so does the demand for high-quality fasteners that can withstand harsh environments and provide long-term reliability. Among the many types of fasteners used today, stainless steel special-shaped bolts have emerged as a preferred choice due to their superior mechanical properties, corrosion resistance, and adaptability to complex installation conditions.

Jiangsu Huajie Stainless Steel Products Co., Ltd., founded in 2003 with a registered capital of 18 million RMB, has grown into one of China's leading manufacturers of stainless steel fasteners. With a factory covering an area of 80,000 square meters and an annual production capacity of 60,000 tons, HuaJie combines extensive industry experience with continuous technological innovation. Over two decades of development, the company has established itself as a competitive player in the global fastener market.

Product Range and Technical Capabilities

HuaJie specializes in the production of stainless steel fasteners that meet international standards such as GB, JIS, DIN, ANSI, and ISO. The company’s product line includes a wide range of bolts, screws, nuts, and washers, among which the stainless steel special-shaped bolts are particularly well-suited for use in automotive applications. These bolts are designed with non-standard geometries to accommodate unique assembly requirements and space constraints commonly found in modern vehicle systems.

The materials used in HuaJie’s products include grades such as 201, 304, and 316L stainless steel, each offering distinct advantages depending on the operating environment. For instance, 304 stainless steel is widely used for its balanced strength and corrosion resistance, while 316L is preferred in highly corrosive or marine environments due to its enhanced molybdenum content.

Equipped with advanced domestic and international production and testing equipment, HuaJie ensures precision in every stage of manufacturing. This commitment to quality control allows the company to consistently deliver products that meet or exceed customer expectations.

Application Advantages in Automotive Fastening Systems

Stainless steel special-shaped bolts produced by HuaJie have demonstrated excellent performance in automotive fastening systems. Their unique design enables them to be installed in tight or irregular spaces where standard bolts may not fit, thereby improving assembly efficiency and structural stability. Moreover, these bolts exhibit strong tensile and shear strength, ensuring reliable connections even under dynamic loads and vibrations typical in automotive operations.

Corrosion resistance is another key factor contributing to the longevity and safety of automotive fasteners. In vehicles, especially electric and hybrid models, fasteners are often exposed to moisture, salt, and chemical agents from both external environments and internal systems such as cooling and battery packs. Stainless steel special-shaped bolts from HuaJie offer excellent resistance to oxidation and chemical degradation, significantly reducing the risk of premature failure and maintenance costs.

Additionally, these fasteners are compatible with lightweight material trends in the automotive industry. As automakers increasingly adopt aluminum, magnesium alloys, and carbon fiber composites to reduce vehicle weight and improve fuel efficiency, the need for fasteners that do not induce galvanic corrosion becomes crucial. Stainless steel fasteners, especially those made from 316L grade, demonstrate minimal reactivity with dissimilar metals, making them ideal for multi-material assemblies.

Quality Assurance and Innovation

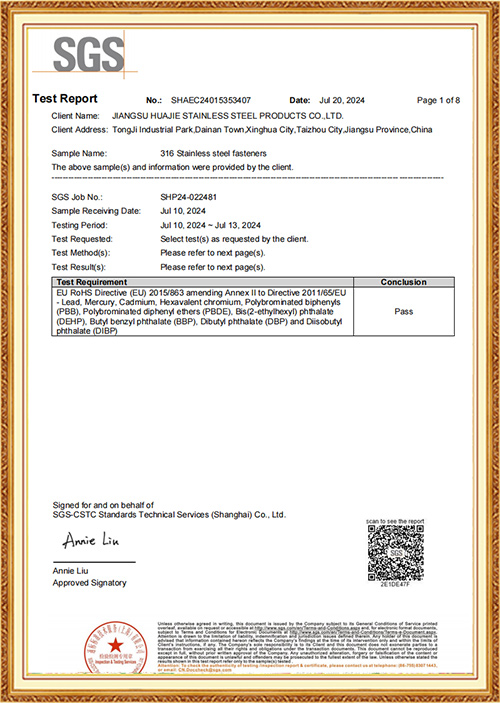

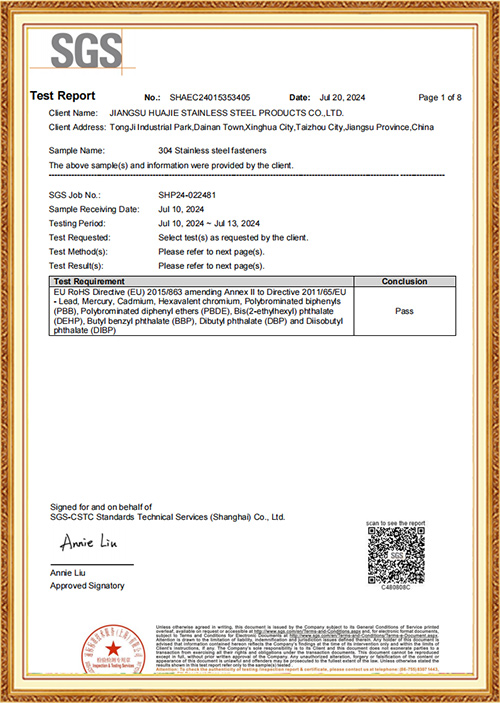

HuaJie has obtained certifications for three major management systems: ISO9001 (Quality Management), ISO14001 (Environmental Management), and ISO18001 (Occupational Health and Safety). These certifications reflect the company’s commitment to sustainable development, operational excellence, and product reliability. Furthermore, HuaJie holds the AAA-level standard of good conduct business and has been recognized with compliance measurement certificates, confirming its adherence to international quality benchmarks.

Innovation lies at the core of HuaJie’s success. The company has established the Jiangsu Enterprise Technology Center and the Taizhou Engineering Technology Research Center, focusing on the research and development of high-performance fasteners. It has also received recognition for new technologies and products from the Jiangsu provincial government and has been awarded the title of National High-Tech Enterprise.

To further strengthen its technical capabilities, HuaJie collaborates closely with institutions such as Jiangsu University and other higher education institutions. Through joint research initiatives, the company continues to refine its stainless steel fastener designs and improve their application performance across various industries, including the automotive sector.

Case Studies and Market Feedback

Several domestic and international automotive manufacturers have adopted HuaJie’s stainless steel special-shaped bolts in their production lines. One notable example is the successful integration of these bolts in the fastening systems of electric vehicle battery modules. Due to the compact design and high sealing requirements of EV battery packs, traditional fasteners often fail to meet the spatial and functional demands. HuaJie’s specially designed bolts provided a perfect solution—offering secure fastening, ease of installation, and long-term durability.

Another case involves the use of HuaJie’s fasteners in engine compartment components, where exposure to high temperatures, oil, and vibration is common. Field tests showed that the stainless steel special-shaped bolts maintained their structural integrity and load-bearing capacity over extended periods, outperforming conventional carbon steel alternatives in terms of service life and maintenance frequency.

Feedback from customers across different regions highlights HuaJie’s ability to deliver customized solutions tailored to specific automotive applications. Engineers and procurement teams appreciate the company’s responsiveness, technical support, and consistent product quality, which contribute to smoother production processes and reduced downtime.

As the automotive industry evolves toward electrification, automation, and lightweight construction, the demand for high-performance fasteners will only continue to grow. Stainless steel special-shaped bolts from Jiangsu Huajie Stainless Steel Products Co., Ltd. represent a strategic advancement in meeting these evolving needs. With their excellent mechanical properties, corrosion resistance, and design flexibility, these fasteners play a vital role in enhancing the safety, efficiency, and durability of automotive fastening systems.

Backed by 20 years of industrial expertise, cutting-edge technology, and a strong commitment to quality, HuaJie is well-positioned to support the next generation of automotive manufacturing. As the company continues to expand its R&D efforts and deepen collaborations with academic and industrial partners, it remains dedicated to delivering innovative fastening solutions that drive progress in the global automotive sector.

English

English русский

русский Deutsch

Deutsch عربى

عربى