Understanding 316 Stainless Steel Threaded Rods 316 stainless steel threaded rods are highly versatile fasteners known for their exceptional corrosion resistanc...

READ MORE

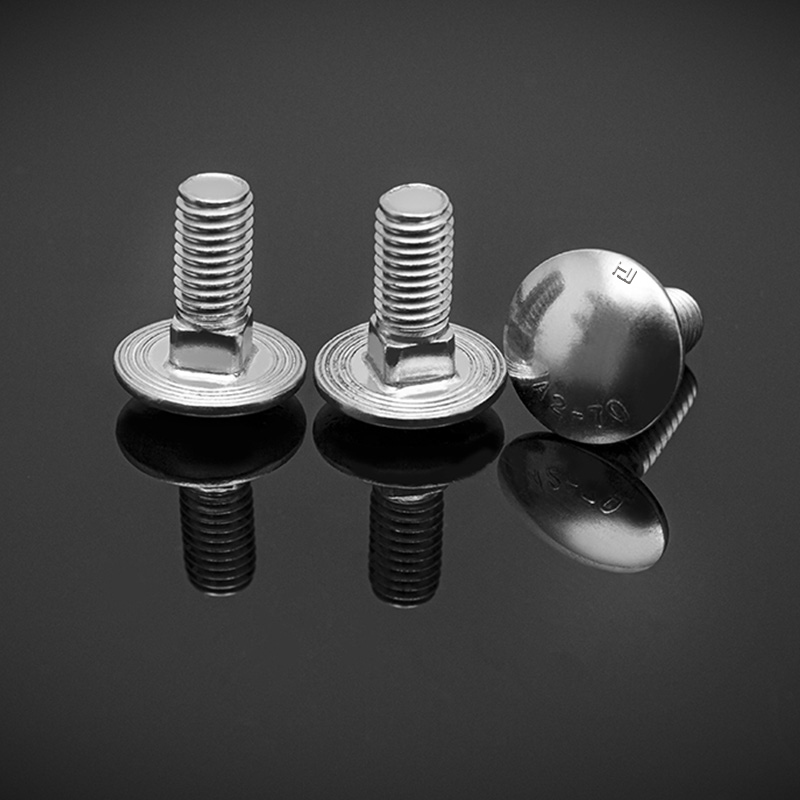

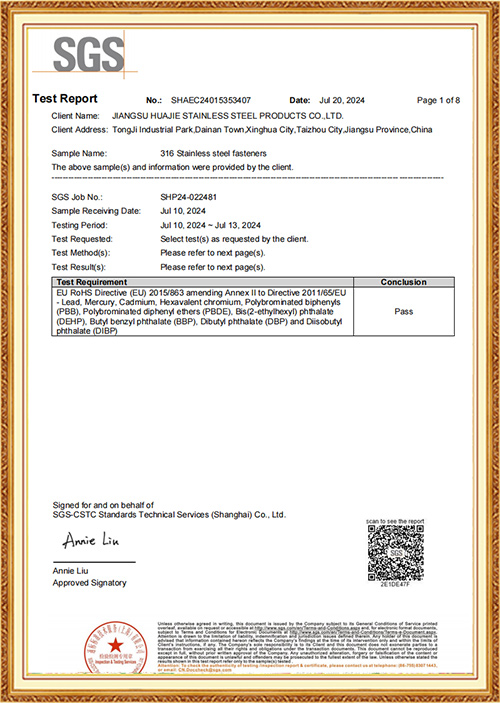

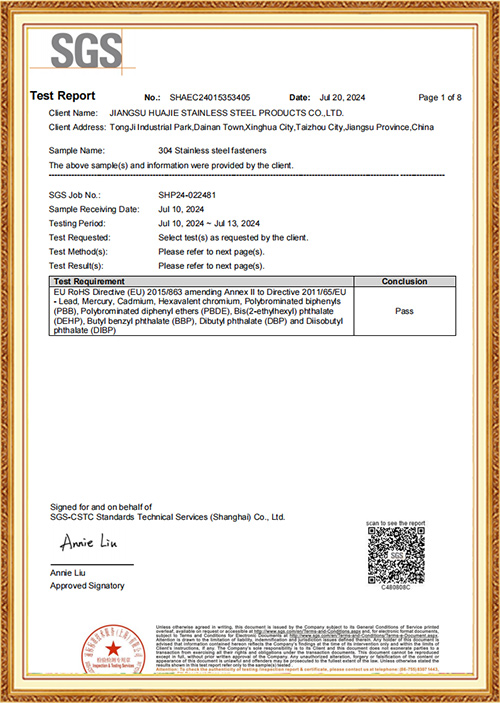

We are Wholesale Stainless Steel Bolts Manufacturers and Stainless Steel Bolts Factory in China, our company mainly produces stainless steel fasteners, The company has domestic and foreign advanced production and testing equipment, and product standards Cover GB/JIS/DIN/ANSI/ISO standards, The material includes 201/304/316L, etc. The products are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemical, military equipment, aerospace, and other fields.

-

-

Introduction to Hex Nuts Hex nuts are one of the most common fasteners used in machinery, construction, and various industrial applications. They are designed t...

READ MORE -

Structural Design Features of Mushroom Head Square Neck Bolts Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and...

READ MORE -

Introduction to High-Strength Stainless Steel Screws High-strength stainless steel screws are essential fasteners for applications that demand durability, corro...

READ MORE

Understanding Bolt Materials: Choosing the Right Alloy for Strength, Durability, and Corrosion Resistance

When selecting bolts for industrial or structural applications, one of the most critical decisions lies in choosing the right material. The performance, safety, and service life of a bolted connection are all closely tied to the bolt’s material composition. This is especially true in sectors like construction, automotive, marine, and heavy equipment manufacturing, where harsh environments and demanding loads make material choice far from a trivial matter. The wrong material can lead to premature failure, corrosion issues, or performance inefficiencies that result in costly downtime.

Among the many options available, stainless steel bolts have carved out a strong reputation for their balance of strength, corrosion resistance, and longevity. Unlike carbon steel bolts, which often require protective coatings, stainless bolts offer inherent resistance to oxidation and chemical exposure due to their chromium content. Grades like 304 and 316 are widely used, with the latter being preferred in more corrosive environments such as coastal or chemical processing settings. This makes stainless bolts a go-to choice for long-term reliability without frequent maintenance.

However, not every application requires stainless steel. In high-stress structural applications, alloy steel bolts may provide better tensile strength and load-bearing capacity. These bolts are heat-treated for maximum hardness and fatigue resistance, making them suitable for bolted joints subject to dynamic loads. That said, alloy bolts generally lack the corrosion resistance of stainless variants and often require surface treatments like zinc plating or galvanizing to meet environmental demands. The decision isn’t simply about performance—it's also about how much protection the material itself provides and the environment in which it will be used.

Understanding the trade-offs between material strength and corrosion resistance is key. For instance, while stainless steel fasteners perform excellently in corrosive environments, they may not match the mechanical strength of certain hardened alloy bolts used in heavy-duty construction. This has led engineers to carefully evaluate not just the mechanical specifications of a bolt, but also the total cost of ownership—considering potential replacements, inspection cycles, and installation environments. The material selected often impacts the overall design philosophy of the structure, especially in mission-critical installations.

Another important consideration is temperature tolerance. Stainless steel bolts can withstand wide thermal ranges without significant loss of performance, which makes them ideal for applications involving heat or rapid temperature changes, such as in power plants or engine components. On the other hand, in extremely high-temperature applications, specialty alloys like Inconel or duplex stainless steels might be necessary to ensure structural integrity over time. This nuanced understanding of alloy performance is essential when working with clients across sectors with varying environmental and technical requirements.

As manufacturers and suppliers, we’ve worked with countless clients facing these decisions, and our role is often to guide the right material selection from both an engineering and procurement perspective. Choosing between different bolt materials isn’t just about immediate functionality—it’s about lifecycle performance, availability, and long-term compatibility with other materials. From supplying standard stainless bolts to developing custom fastening solutions, we focus on material integrity that aligns with real-world usage, not just lab conditions.

For buyers, engineers, or procurement teams, the takeaway is this: never underestimate the role of bolt materials in your project's success. A well-informed material choice can dramatically extend the lifespan of your assemblies, reduce maintenance costs, and improve operational safety. Whether you're sourcing stainless steel bolts for a marine project or exploring high-strength fasteners for industrial use, choosing the right alloy is not just a technical choice—it’s a strategic investment.

English

English русский

русский Deutsch

Deutsch عربى

عربى