+86 189 6101 2359

+86 133 6521 5663

+86 138 5268 6835

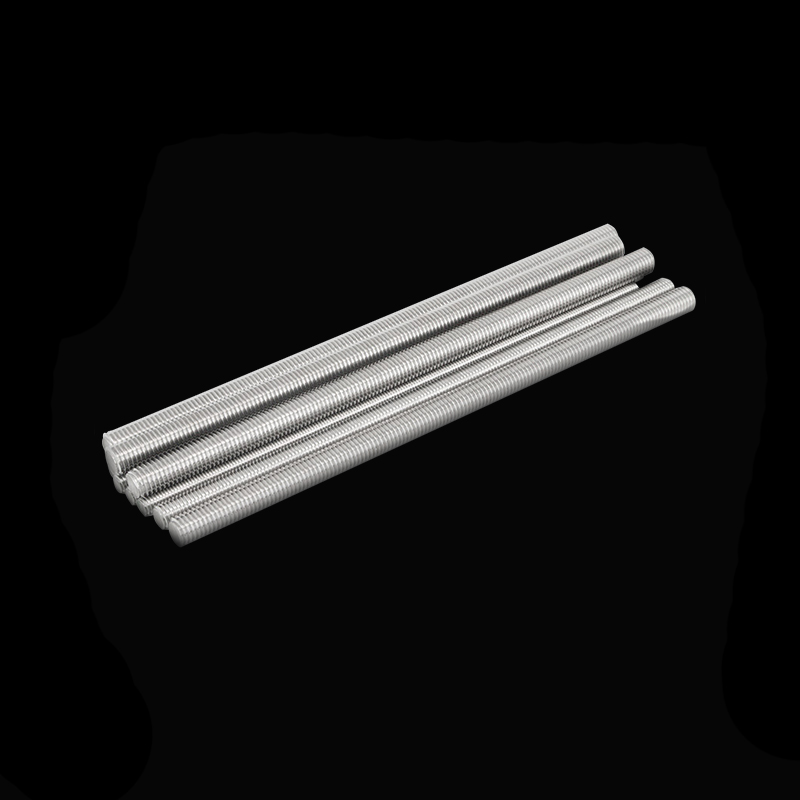

Stainless steel threaded rods are widely used in construction, marine, chemical, and industrial applications due to their strength, durability, and resistance to corrosion. Among the common grades, 316 and 304 stainless steel rods are often compared for their performance in harsh environments. Understanding the differences between 316 and 304 stainless steel threaded rods, particularly in corrosion resistance and mechanical strength, is crucial for selecting the right material for your project.

Content

316 stainless steel is an austenitic stainless steel alloy containing higher levels of chromium, nickel, and the addition of molybdenum, which enhances its resistance to pitting and crevice corrosion in chloride-rich environments. In contrast, 304 stainless steel contains slightly lower nickel content and no molybdenum, providing good general corrosion resistance but lower performance in highly corrosive or marine environments.

Corrosion resistance is a critical factor when selecting stainless steel threaded rods, especially in outdoor, marine, or chemical exposure conditions. 316 stainless steel exhibits superior resistance to pitting and crevice corrosion due to the presence of molybdenum. This makes it particularly suitable for applications such as coastal construction, seawater systems, and chemical processing plants. 304 stainless steel performs well in indoor or mild environments but is more susceptible to corrosion when exposed to chlorides, acidic solutions, or high-humidity conditions.

| Property | 316 Stainless Steel | 304 Stainless Steel |

| Chloride Resistance | Excellent | Moderate |

| Pitting and Crevice Corrosion | High Resistance | Low to Moderate |

| Suitability for Marine Environments | Recommended | Limited |

| General Outdoor Applications | Excellent | Good |

Both 316 and 304 stainless steel threaded rods offer strong mechanical properties suitable for structural and fastening applications. 316 stainless steel generally has slightly higher tensile and yield strength compared to 304, which improves performance under heavy load or high-stress conditions. The differences may be subtle, but in demanding applications such as chemical plants, marine structures, or high-stress outdoor installations, 316 rods provide an extra margin of safety.

Choosing between 316 and 304 stainless steel threaded rods depends on environmental conditions, mechanical requirements, and budget constraints. 316 is preferred for corrosive or marine environments, chemical processing, and any application where chloride exposure is likely. 304 is suitable for indoor, mild outdoor, or non-corrosive environments where cost efficiency is important. Additionally, 316 rods are often specified for projects requiring extended service life and minimal maintenance.

While both 316 and 304 stainless steel threaded rods provide reliable strength and corrosion resistance, 316 stainless steel offers superior performance in highly corrosive, marine, and chemical environments due to its molybdenum content. 304 stainless steel remains a cost-effective option for less demanding conditions. By evaluating environmental exposure, mechanical load requirements, and long-term durability needs, engineers and project managers can select the appropriate stainless steel grade to ensure structural integrity, reliability, and longevity of threaded connections.

ThreadTolerance: 6gstandardDIN 13-15、DIN 13-12Rod diameter dd≤M20:A2-70、A4-70;M20<d≤M39:A2-50、A4-50;d≥M39:C3、C4;d<M39

See DetailsCopyright © Jiangsu Huajie Stainless Steel Products Co., Ltd. All Rights Reserved.

Stainless Steel Fasteners Manufacturers