Understanding 316 Stainless Steel Threaded Rods 316 stainless steel threaded rods are highly versatile fasteners known for their exceptional corrosion resistanc...

READ MORE

We are Wholesale Stainless Steel Threaded Rods & Studs Suppliers and Stainless Steel Threaded Rods & Studs Company in China, our company mainly produces stainless steel fasteners, The company has domestic and foreign advanced production and testing equipment, and product standards Cover GB/JIS/DIN/ANSI/ISO standards, The material includes 201/304/316L, etc. The products are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemical, military equipment, aerospace, and other fields.

-

-

Introduction to Hex Nuts Hex nuts are one of the most common fasteners used in machinery, construction, and various industrial applications. They are designed t...

READ MORE -

Structural Design Features of Mushroom Head Square Neck Bolts Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and...

READ MORE -

Introduction to High-Strength Stainless Steel Screws High-strength stainless steel screws are essential fasteners for applications that demand durability, corro...

READ MORE

Threaded Rods vs. Traditional Fasteners: Benefits in Modular Installations

In modular installations where components must be frequently assembled, adjusted, or relocated, the choice of fastening solutions plays a significant role in both efficiency and structural reliability. Among various options, threaded rods—also known as tooth bars—stand out as a practical and adaptable solution. Compared to traditional fasteners like bolts and screws, threaded rods offer distinct advantages, particularly in construction, industrial frames, and equipment guardrail assemblies.

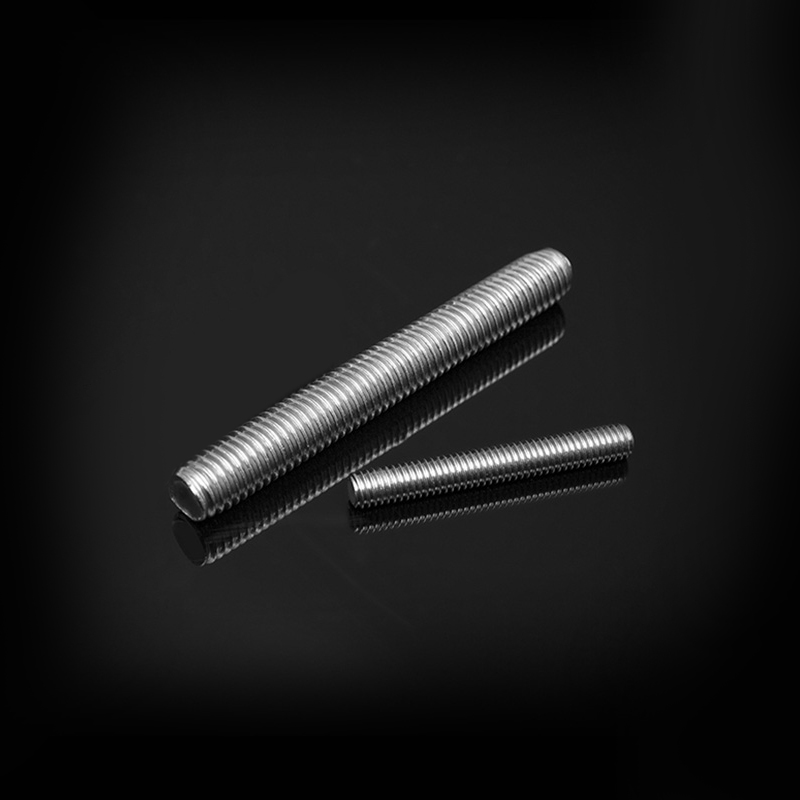

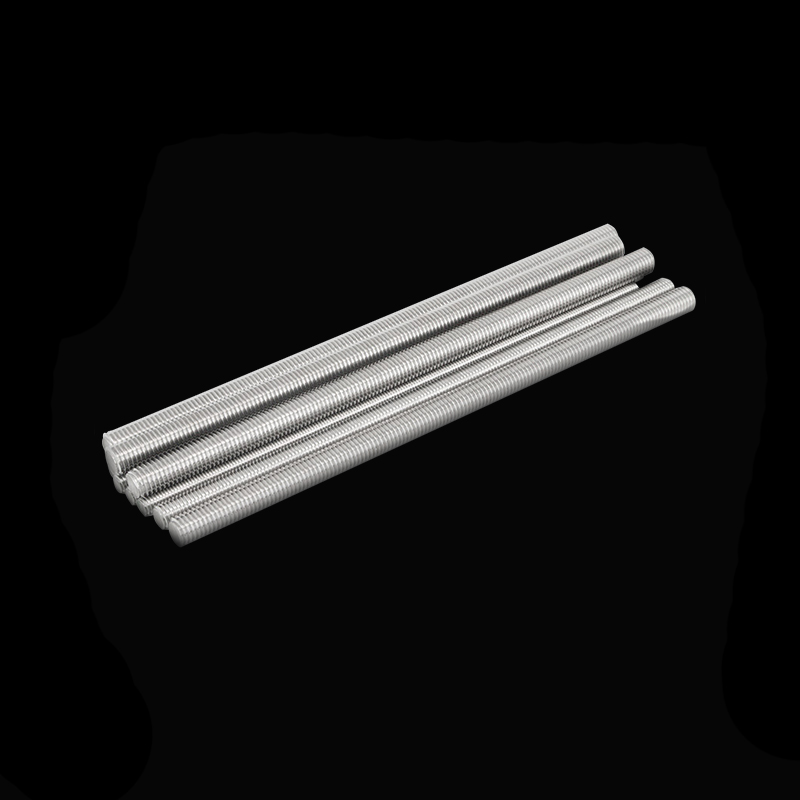

Unlike traditional fasteners that usually have a head and a limited engagement depth, a threaded rod is a long, cylindrical part with external threads running along its entire length. Its headless and uniform structure allows for flexible positioning, length customization, and secure fastening from both ends when used with nuts. This makes threaded rods highly suitable for modular systems that require disassembly, extension, or repositioning without damaging the components.

A prime example of this is in scaffolding systems. Here, stainless steel threaded rods allow for easy and precise adjustment of connection length and tightness. Their simplicity in structure means fewer parts are needed, reducing complexity and potential points of failure. In addition, they perform well in frame structures that undergo repeated assembly, such as those used in industrial equipment and infrastructure setups.

The efficiency of threaded rods begins at the manufacturing stage. Typically produced using cold drawing or rolling techniques, the raw blank achieves the desired diameter and surface quality with high consistency. For longer rods, additional straightening processes are applied to meet strict linearity standards. Thread creation is most commonly performed through thread rolling—a high-speed, high-precision method where threads are formed by pressing the rod surface with rolling dies. This not only enhances thread strength but also increases production efficiency, making it ideal for large-scale applications. In some high-precision use cases, thread turning may be applied despite its lower efficiency.

Among the companies specializing in the production of stainless steel threaded rods, Jiangsu Huajie Stainless Steel Products Co., Ltd. has earned a strong reputation. Founded in 2003 with a registered capital of 18 million RMB, Huajie operates a manufacturing base covering 80,000 square meters and boasts an annual production capacity of 60,000 tons. The company focuses on stainless steel fasteners, offering products that comply with GB, JIS, DIN, ANSI, and ISO standards. Available materials include 201, 304, and 316L stainless steel, catering to various demands across industries such as high-speed rail, petrochemical, mechanical equipment, new energy, and aerospace.

In modular installations, threaded rods outperform traditional fasteners in terms of adaptability, strength, and installation speed. Their full-length thread design allows for fine-tuned tensioning and alignment, essential in systems where precise fitting and stability are required. Moreover, in environments where components are exposed to vibration, temperature shifts, or mechanical stress, threaded rods maintain integrity without needing complex tightening sequences.

Choosing a stainless steel threaded rod over conventional bolts or screws also brings long-term value. Stainless steel offers corrosion resistance and longevity, reducing maintenance frequency in both indoor and outdoor settings. In modular setups—whether temporary or permanent—this translates into reduced downtime and labor costs.

With two decades of experience, Jiangsu Huajie continues to deliver reliable solutions tailored to evolving engineering needs. Its commitment to quality, customer service, and innovation positions the company as a competitive stainless steel fastener manufacturer in China. Whether used in dynamic construction projects or precision industrial assemblies, Huajie’s threaded rods combine proven manufacturing expertise with practical application benefits, making them a strong alternative to traditional fasteners in today’s modular installations.

Stainless Steel Threaded Studs: Combining Strength, Flexibility, and Reliability

Stainless steel threaded studs have become a critical component across various industries, thanks to their ability to combine strength, flexibility, and reliability in demanding environments. These cylindrical fasteners, fully threaded along their length and free from complex heads or additional shaping, are widely used where high performance, adaptability, and secure connections are essential. In modular constructions, industrial frameworks, and heavy equipment, stainless steel threaded studs offer a dependable solution for precise, durable, and adjustable fastening.

One of the key advantages of stainless steel threaded studs lies in their structural simplicity and versatility. Unlike bolts or screws that often include heads or partial threading, threaded studs provide uniform threading along their full length. This design enables double-ended fastening with nuts on either side, making it easy to adjust the connection tightness and length based on different installation needs. Whether used for scaffolding in the construction sector or in guardrails on industrial equipment, their adaptability proves valuable in applications requiring regular assembly, disassembly, and realignment.

In terms of manufacturing, threaded studs benefit from efficient and cost-effective processes. Cold drawing or rolling is typically employed to refine the raw material, shaping it into a precise diameter with high surface quality and straightness. These production methods allow for consistent output and reduced material waste. For longer studs, additional straightening treatment ensures that straightness remains within tolerances. When it comes to thread formation, thread rolling is the most common technique. This method uses thread rolling dies to press the threads into the rod surface, resulting in smooth, high-precision threads with enhanced tensile strength—ideal for mass production. In specific cases that demand extremely fine tolerances, thread turning may be used, though it requires more time and labor.

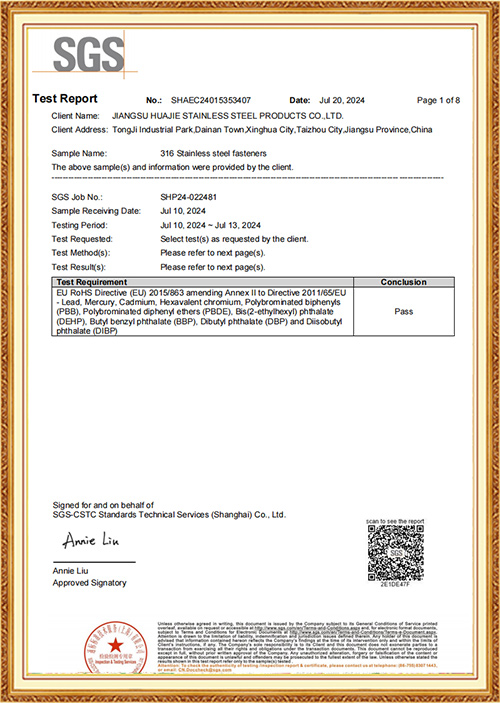

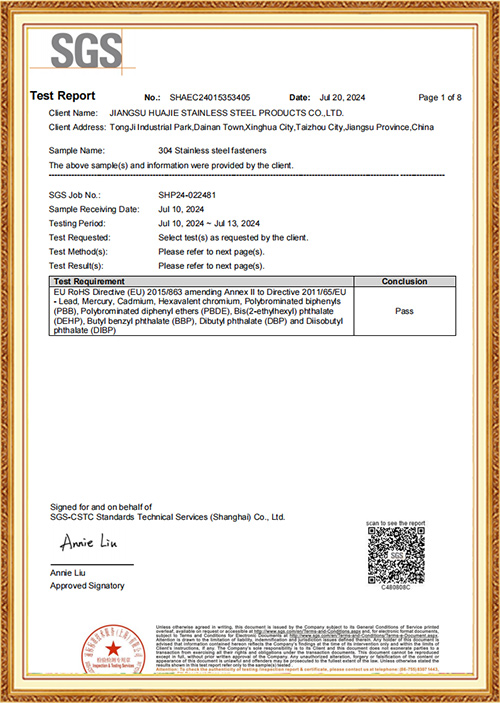

Huajie’s stainless steel fasteners are manufactured from high-grade materials such as 201, 304, and 316L stainless steel, catering to a wide range of environments and performance needs. These materials are selected for their corrosion resistance, mechanical strength, and long service life, making them suitable for challenging industries such as high-speed rail, nuclear power, petrochemical, new energy, aerospace, military, and heavy machinery. With state-of-the-art production lines and advanced inspection equipment, Huajie ensures that each threaded stud meets stringent quality and safety requirements.

In addition to its robust production capabilities, Huajie has achieved numerous certifications and recognitions that underscore its commitment to quality and innovation. The company has passed ISO19001, ISO14001, and ISO18001 management system certifications. It has also been awarded the AAA-level standard of good conduct business and possesses certifications for compliance measurement and international product standards. Furthermore, Huajie owns the Jiangsu Enterprise Technology Center and the Taizhou Engineering Technology Research Center and has received official recognition for new technologies and products in Jiangsu Province.

"Quality First, Customers First" has always been Huajie’s operating principle. The company welcomes clients from both domestic and international markets to explore cooperative opportunities. By integrating precision manufacturing with durable materials and flexible design, Huajie’s stainless steel threaded studs stand out as a reliable solution for modern engineering applications—delivering performance you can count on in every project.

English

English русский

русский Deutsch

Deutsch عربى

عربى