Understanding 316 Stainless Steel Threaded Rods 316 stainless steel threaded rods are highly versatile fasteners known for their exceptional corrosion resistanc...

READ MORE

We are Wholesale Stainless Steel Double Headed Bolts Suppliers and Stainless Steel Double Headed Bolts Company in China, our company mainly produces stainless steel fasteners, The company has domestic and foreign advanced production and testing equipment, and product standards Cover GB/JIS/DIN/ANSI/ISO standards, The material includes 201/304/316L, etc. The products are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemical, military equipment, aerospace, and other fields.

-

-

Introduction to Hex Nuts Hex nuts are one of the most common fasteners used in machinery, construction, and various industrial applications. They are designed t...

READ MORE -

Structural Design Features of Mushroom Head Square Neck Bolts Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and...

READ MORE -

Introduction to High-Strength Stainless Steel Screws High-strength stainless steel screws are essential fasteners for applications that demand durability, corro...

READ MORE

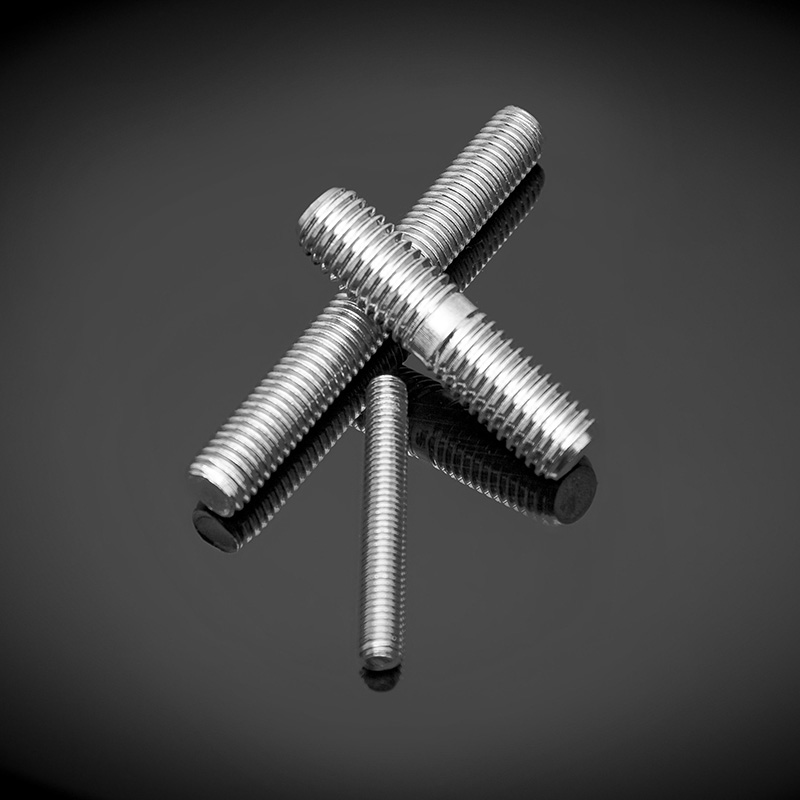

A Guide to the Uses and Production Methods of Stainless Steel Double Headed Studs

Stainless steel double headed studs are specialized fasteners with threads on both ends and a smooth shank in the middle. This design makes them ideal for applications where two components need to be securely joined but cannot be connected directly with standard bolts. One end of the stud is screwed into a pre-threaded hole, while the other end is used to secure a nut. This fastening method is especially valuable in complex assemblies, offering both strength and reliability.

One of the most common applications of stainless steel double headed studs is in the automotive industry, particularly in the connection between the cylinder block and the cylinder head of engines. The cylinder block often features threaded holes where one end of the stud is fixed. The other end extends out and connects to the cylinder head with a nut. This approach not only simplifies disassembly for maintenance but also ensures a stable and leak-resistant connection under high-pressure and high-temperature conditions. Beyond automotive uses, these studs are widely employed in machinery, aerospace, new energy systems, and heavy equipment.

The production of stainless steel double headed studs involves precision engineering. A frequently used method for forming threads is the thread-rolling process. This involves placing the billet between two rolling plates that move in opposite directions, imprinting the thread profile onto the surface through cold forming. This technique is efficient and well-suited for mass production due to its speed and consistency. For larger diameter studs or applications requiring tighter tolerances, manufacturers may use turning or rolling processes to achieve the necessary thread accuracy and finish.

Jiangsu Huajie Stainless Steel Products Co., Ltd. is one of the key players in the stainless steel fastener industry, specializing in products such as double headed studs. Established in 2003, Huajie has grown over the years to become a major manufacturer, covering an area of 80,000 square meters with an annual production capacity of 60,000 tons. With a registered capital of 18 million RMB, the company has continually invested in advanced production lines and testing equipment to maintain high standards across all stages of manufacturing.

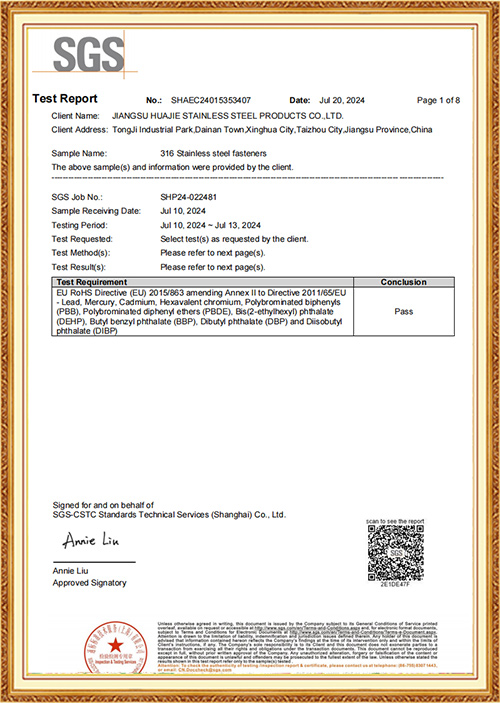

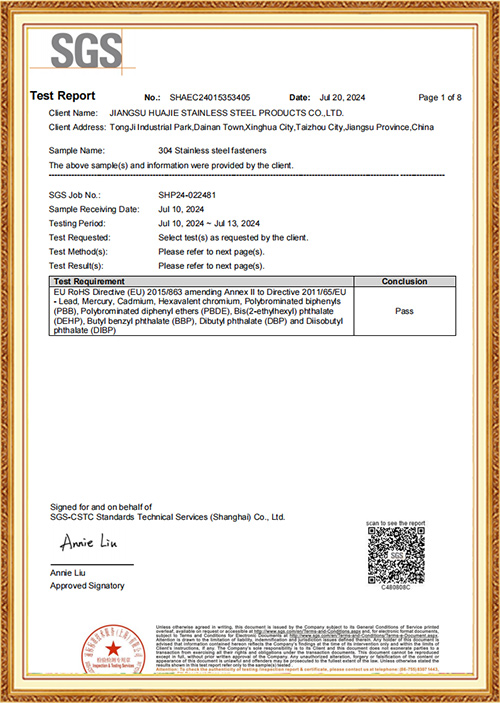

The company offers stainless steel fasteners made from materials such as 201, 304, and 316L, and complies with a wide range of international standards including GB, JIS, DIN, ANSI, and ISO. These standards ensure that Huajie’s double headed studs meet the rigorous requirements of industries like high-speed rail, nuclear power, petrochemicals, telecommunications, and even military and aerospace applications. This broad applicability highlights the versatility and reliability of the company’s products.

In terms of quality assurance and innovation, Jiangsu Huajie has passed ISO19001, ISO14001, and ISO18001 management system certifications, reflecting a strong commitment to quality, environmental sustainability, and occupational health and safety. The company also holds AAA-level business credit and has been recognized with certifications such as the compliance measurement certificate. Its technical strength is further backed by R&D collaborations with academic institutions including Jiangsu University, and the company operates its own technology centers at the provincial and city levels.

Huajie’s approach to manufacturing is grounded in innovation, reliability, and quality. The firm has received recognition for new technology and product development in Jiangsu Province and has been honored as a national high-tech enterprise. These accolades underscore Huajie’s capability to produce stainless steel double headed studs that meet the demands of both domestic and international clients.

Stainless steel double headed studs play a crucial role in precision fastening applications across various industries. From engine assembly in automobiles to structural connections in high-tech sectors, these studs offer dependable performance. With companies like Jiangsu Huajie leading the way in production and innovation, customers can rely on high-quality fastening solutions that combine advanced manufacturing techniques with industry-specific expertise. As always, Huajie adheres to the principle of “Quality First, Customers First,” inviting clients worldwide to explore collaborative opportunities and contribute to shared success.

English

English русский

русский Deutsch

Deutsch عربى

عربى