Understanding 316 Stainless Steel Threaded Rods 316 stainless steel threaded rods are highly versatile fasteners known for their exceptional corrosion resistanc...

READ MORE

We are Wholesale Stainless Steel Slotted Screws Suppliers and Stainless Steel Slotted Screws Company in China, our company mainly produces stainless steel fasteners, The company has domestic and foreign advanced production and testing equipment, and product standards Cover GB/JIS/DIN/ANSI/ISO standards, The material includes 201/304/316L, etc. The products are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemical, military equipment, aerospace, and other fields.

-

-

Introduction to Hex Nuts Hex nuts are one of the most common fasteners used in machinery, construction, and various industrial applications. They are designed t...

READ MORE -

Structural Design Features of Mushroom Head Square Neck Bolts Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and...

READ MORE -

Introduction to High-Strength Stainless Steel Screws High-strength stainless steel screws are essential fasteners for applications that demand durability, corro...

READ MORE

Are Jiangsu Huajie Stainless Steel 's Stainless Steel Slotted Screws Suitable for High-Temperature Applications

When it comes to fastening solutions in thermally demanding environments, every detail matters. The type of screw, the precision of its machining, the integrity of its material—all play critical roles. In industries where heat is not a variable but a constant, choosing the right fastener isn't just smart—it's essential. Among the many options available, stainless steel slotted screws remain a dependable choice for general-purpose applications. But can they truly endure high-temperature scenarios?

Anatomy of a Slotted Screw: Simple Design, Targeted Utility

Slotted screws are defined by a single, linear groove across the head, specifically engineered for flat-blade screwdrivers. While their simplicity is one of their strengths, this very characteristic also imposes a limitation: their torque-bearing capacity is relatively low. For applications involving frequent vibrations or high structural stress, alternative drives—like Torx or hex—might be more suitable.

However, for standard connections, especially where finesse and visual discretion are priorities, slotted screws prove their worth. They’re prevalent in furniture assembly, consumer electronics, and light mechanical constructions. Their straightforward geometry allows for easy manual installation and a clean aesthetic finish.

Versatility Across Head Types

Jiangsu Huajie's product range includes various slotted head styles, each tailored for specific use cases:

Pan Head and Cylindrical Head Slotted Screws: Ideal for general structural connections where surface mounting is acceptable.

Semi-Countersunk Slotted Screws: Frequently used in instruments and precision machinery, offering a semi-flush finish.

Countersunk Slotted Screws: Designed for applications where the screw head must sit flush with the surface—function meets subtlety.

Slotted Headless Screws: A favored solution in the furniture sector for clean lines and efficient assembly, enhancing both durability and visual appeal.

These variations, combined with meticulous manufacturing, allow slotted screws to cover a broad spectrum of installation environments.

The Crucial Role of Material Composition

No discussion of heat resistance is complete without examining the material science behind the screw. Jiangsu Huajie offers slotted screws crafted from 201, 304, and 316L stainless steels—each with its own thermal properties:

201 Stainless Steel: Offers decent strength and corrosion resistance but is less ideal for sustained high-temperature environments.

304 Stainless Steel: The industry standard, providing excellent corrosion resistance and enduring temperatures up to approximately 870°C intermittently.

316L Stainless Steel: Enhanced with molybdenum, 316L exhibits superior resistance to pitting and oxidation, performing reliably in temperatures approaching 925°C in intermittent exposure.

For high-temperature applications, 304 and 316L variants are the optimal choices. They retain structural integrity, resist scaling, and minimize creep under thermal stress. When sourced from a reputable manufacturer, these grades offer the confidence engineers and designers seek in elevated-temperature conditions.

Why Jiangsu Huajie Stainless Steel Products Co., Ltd.?

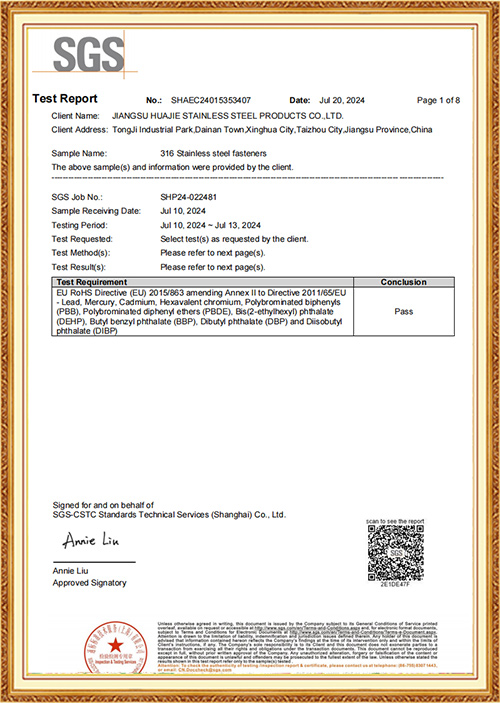

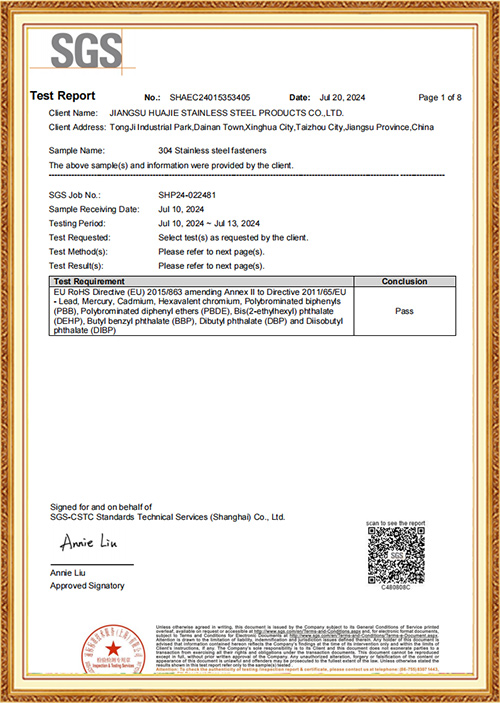

Founded in 2003, Jiangsu Huajie has established itself as a pillar in China's stainless steel fastener sector. With a 13,000-square-meter facility, a registered capital of 18 million RMB, and an annual production capacity of 60,000 tons, Huajie is more than a manufacturer—it is a benchmark for excellence.

Their adherence to GB, JIS, DIN, ANSI, and ISO standards, along with the use of globally respected stainless steel grades, ensures every screw leaving the production line is engineered to perform.

Backed by over two decades of manufacturing experience, Huajie serves a diverse range of sectors—including nuclear energy, aerospace, high-speed rail, petrochemical, military, and advanced mechanical engineering. The company’s investments in both domestic and international testing equipment reinforce its commitment to quality assurance at every stage.

When reliability under pressure is paramount, Huajie's stainless steel slotted screws rise to the challenge.

While slotted screws may not be the first choice for every high-torque or vibration-prone environment, Jiangsu Huajie's stainless steel slotted screws—especially those made from 304 and 316L—are absolutely suitable for high-temperature applications where their structural simplicity, clean finish, and material resilience align with the demands of the job.

When quality, temperature tolerance, and long-term performance converge, one name continues to stand out: Jiangsu Huajie Stainless Steel Products Co., Ltd.—where precision meets endurance.

English

English русский

русский Deutsch

Deutsch عربى

عربى