Understanding 316 Stainless Steel Threaded Rods 316 stainless steel threaded rods are highly versatile fasteners known for their exceptional corrosion resistanc...

READ MORE

We are Wholesale Stainless Steel Set Screws Suppliers and Stainless Steel Set Screws Company in China, our company mainly produces stainless steel fasteners, The company has domestic and foreign advanced production and testing equipment, and product standards Cover GB/JIS/DIN/ANSI/ISO standards, The material includes 201/304/316L, etc. The products are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemical, military equipment, aerospace, and other fields.

-

-

Introduction to Hex Nuts Hex nuts are one of the most common fasteners used in machinery, construction, and various industrial applications. They are designed t...

READ MORE -

Structural Design Features of Mushroom Head Square Neck Bolts Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and...

READ MORE -

Introduction to High-Strength Stainless Steel Screws High-strength stainless steel screws are essential fasteners for applications that demand durability, corro...

READ MORE

How Do Jiangsu Huajie Stainless Steel's Stainless Steel Set Screws Perform in High Vibration Environments

In the relentless hum of high-vibration environments—where machines grind, engines pulse, and infrastructure bears cyclical strain—the integrity of every fastening point becomes non-negotiable. A single lapse in fixation can cascade into catastrophic failure. It’s in these extreme conditions that the unassuming set screw must prove its worth.

At the forefront of fastening technology stands Jiangsu Huajie Stainless Steel Products Co., Ltd., a name synonymous with precision-engineered stainless steel fasteners. Established in 2003 with a registered capital of 18 million RMB, Huajie has evolved into one of China’s most formidable manufacturers in the field. Operating out of a 13,000-square-meter production facility, the company delivers an impressive annual output of 60,000 tons, underpinned by two decades of innovation and industrial mastery.

Engineered for Endurance

Stainless steel set screws are not merely components—they are critical sentinels safeguarding mechanical alignment, component positioning, and structural cohesion. Designed without a traditional head and often threaded along the full length of the shaft, these screws deliver localized clamping force to hold parts together under duress.

Huajie’s stainless steel set screws are available in a range of materials—including 201, 304, and 316L stainless steel—selected for their superior corrosion resistance, tensile strength, and thermal stability. These qualities are indispensable in high-vibration environments such as aerospace assemblies, petrochemical installations, rail systems, military hardware, and high-precision electronic equipment.

Tailored Tips for Tactical Applications

The secret to set screw performance lies in its end geometry—each tailored for a specific mechanical scenario:

Tapered (cone) ends: Ideal for low-hardness surfaces, the pointed tip penetrates slightly into the mating part, securing a tight grip and minimizing slippage under vibration.

Flat ends: Best suited for hard, flat surfaces or applications requiring regular repositioning, these ends resist marring while offering consistent pressure.

Cylindrical (dog) ends: Designed to locate precisely within a shaft groove or bore, ensuring axial alignment without damaging the surface.

In environments where movement is constant and tolerances are tight, Huajie's ability to deliver these varied configurations provides engineers with the exact tool for the job.

Head Shapes & Manufacturing Precision

Huajie’s set screws feature an array of head designs—conical, concave, flat—each crafted to meet specific installation and load-bearing needs. The complexity of these geometries demands a sophisticated manufacturing process. Conical heads undergo precision grinding; concave variants require custom molds and intricate stamping or forging techniques. It’s not just metal—it’s mechanical artistry.

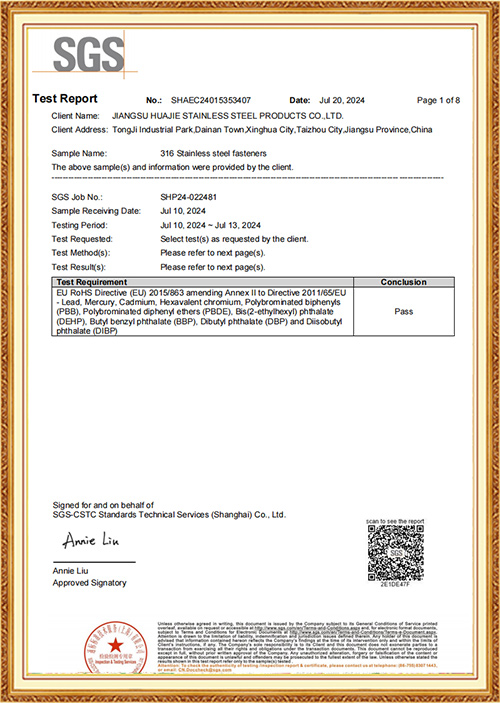

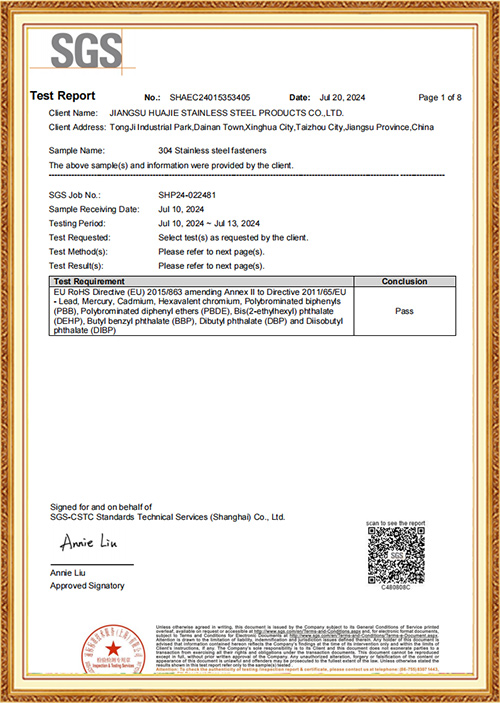

All products adhere strictly to GB, JIS, DIN, ANSI, and ISO standards, and are inspected using advanced testing equipment sourced from both domestic and international markets. This rigorous process ensures consistency in dimensions, surface treatment, thread quality, and mechanical properties.

In the relentless hum of high-vibration environments—where machines grind, engines pulse, and infrastructure bears cyclical strain—the integrity of every fastening point becomes non-negotiable. A single lapse in fixation can cascade into catastrophic failure. It’s in these extreme conditions that the unassuming set screw must prove its worth.

At the forefront of fastening technology stands Jiangsu Huajie Stainless Steel Products Co., Ltd., a name synonymous with precision-engineered stainless steel fasteners. Established in 2003 with a registered capital of 18 million RMB, Huajie has evolved into one of China’s most formidable manufacturers in the field. Operating out of a 13,000-square-meter production facility, the company delivers an impressive annual output of 60,000 tons, underpinned by two decades of innovation and industrial mastery.

Engineered for Endurance

Stainless steel set screws are not merely components—they are critical sentinels safeguarding mechanical alignment, component positioning, and structural cohesion. Designed without a traditional head and often threaded along the full length of the shaft, these screws deliver localized clamping force to hold parts together under duress.

Huajie’s stainless steel set screws are available in a range of materials—including 201, 304, and 316L stainless steel—selected for their superior corrosion resistance, tensile strength, and thermal stability. These qualities are indispensable in high-vibration environments such as aerospace assemblies, petrochemical installations, rail systems, military hardware, and high-precision electronic equipment.

Tailored Tips for Tactical Applications

The secret to set screw performance lies in its end geometry—each tailored for a specific mechanical scenario:

Tapered (cone) ends: Ideal for low-hardness surfaces, the pointed tip penetrates slightly into the mating part, securing a tight grip and minimizing slippage under vibration.

Flat ends: Best suited for hard, flat surfaces or applications requiring regular repositioning, these ends resist marring while offering consistent pressure.

Cylindrical (dog) ends: Designed to locate precisely within a shaft groove or bore, ensuring axial alignment without damaging the surface.

In environments where movement is constant and tolerances are tight, Huajie's ability to deliver these varied configurations provides engineers with the exact tool for the job.

Head Shapes & Manufacturing Precision

Huajie’s set screws feature an array of head designs—conical, concave, flat—each crafted to meet specific installation and load-bearing needs. The complexity of these geometries demands a sophisticated manufacturing process. Conical heads undergo precision grinding; concave variants require custom molds and intricate stamping or forging techniques. It’s not just metal—it’s mechanical artistry.

All products adhere strictly to GB, JIS, DIN, ANSI, and ISO standards, and are inspected using advanced testing equipment sourced from both domestic and international markets. This rigorous process ensures consistency in dimensions, surface treatment, thread quality, and mechanical properties.

English

English русский

русский Deutsch

Deutsch عربى

عربى