Understanding 316 Stainless Steel Threaded Rods 316 stainless steel threaded rods are highly versatile fasteners known for their exceptional corrosion resistanc...

READ MORE

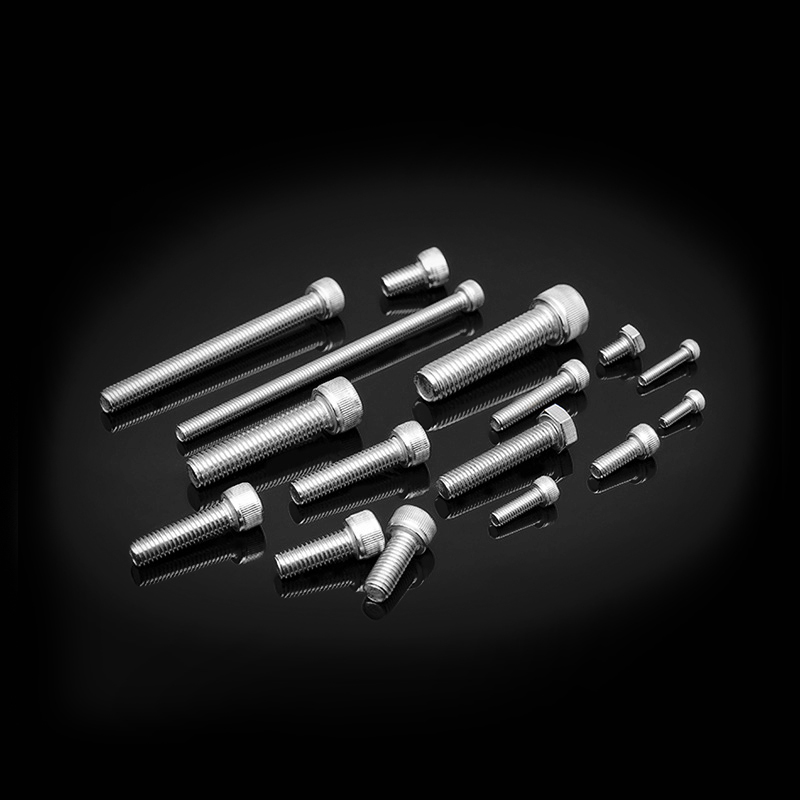

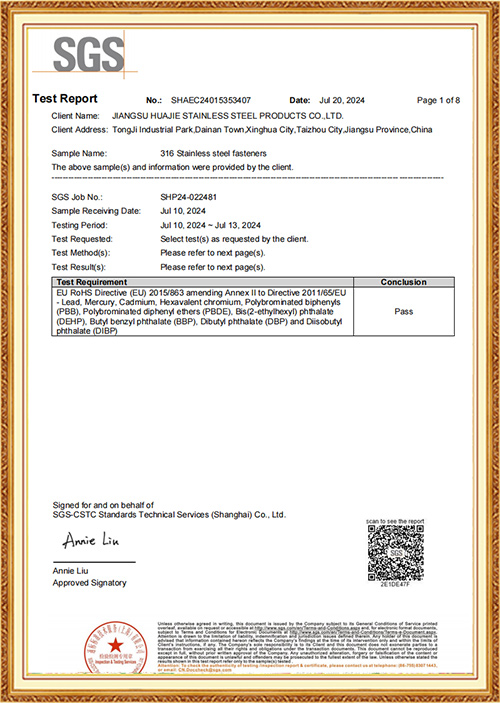

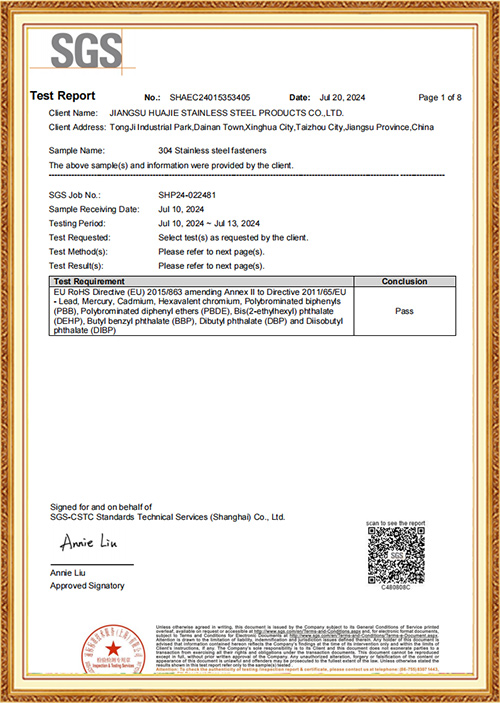

We are Wholesale Stainless Steel Screws Manufacturers and Stainless Steel Screws Factory in China, our company mainly produces stainless steel fasteners, The company has domestic and foreign advanced production and testing equipment, and product standards Cover GB/JIS/DIN/ANSI/ISO standards, The material includes 201/304/316L, etc. The products are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemical, military equipment, aerospace, and other fields.

-

-

Introduction to Hex Nuts Hex nuts are one of the most common fasteners used in machinery, construction, and various industrial applications. They are designed t...

READ MORE -

Structural Design Features of Mushroom Head Square Neck Bolts Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and...

READ MORE -

Introduction to High-Strength Stainless Steel Screws High-strength stainless steel screws are essential fasteners for applications that demand durability, corro...

READ MORE

Understanding Thread Design and Pitch: How Screws Deliver Strength, Precision, and Reliability

When selecting screws for industrial or commercial use, one of the most overlooked yet crucial factors is thread design. Thread geometry directly influences how force is distributed along the fastener, the amount of torque required for installation, and the long-term reliability of the connection. This is particularly important in precision assemblies or load-bearing joints, where even minor thread mismatches can lead to loosening, deformation, or outright failure. From furniture manufacturing to electronic housings, a deep understanding of how thread pitch and profile work can significantly improve your fastening outcomes.

Thread pitch, which refers to the distance between threads, plays a decisive role in how a screw behaves under pressure. Coarse threads, with a wider pitch, are generally more suitable for softer materials like plastics or wood, offering faster insertion and greater resistance to stripping. Fine threads, on the other hand, provide better load distribution, increased tensile strength, and enhanced vibration resistance—making them ideal for metal-to-metal applications. This is why in high-precision industries like automotive and aerospace, engineers often favor fine-threaded stainless steel screws to ensure long-term performance under dynamic stresses.

Beyond pitch, the thread angle and shape also dictate how the screw interacts with its mating material. The standard 60-degree thread angle used in most machine screws is designed to balance ease of manufacture with mechanical strength. However, alternative profiles such as buttress or square threads can be used for specialized applications where axial load performance or minimal friction is critical. The lead of the screw—the distance the screw advances in one full rotation—also affects efficiency and is closely related to pitch, particularly in multi-start threads used in high-speed assemblies.

In manufacturing, a seemingly minor change in thread type can lead to major improvements in assembly line efficiency and product longevity. For instance, self-tapping screws with optimized thread pitches can reduce the need for pre-drilled holes, speeding up production without compromising structural integrity. Machine screws, when matched precisely with threaded inserts or nuts of corresponding pitch, create consistent, repeatable joints that meet rigorous quality standards. This is especially vital for OEMs looking to maintain tight tolerances across large production volumes.

Material selection further influences how threads perform. Stainless steel screws, known for their corrosion resistance and strength, are commonly used in environments where durability is non-negotiable. However, due to their hardness, they may require thread designs that minimize galling or seizing during installation. This makes thread geometry a critical part of screw engineering, not just from a mechanical standpoint but also in terms of material compatibility. A poor fit between thread design and material properties can result in inefficient fastening and increased rejection rates.

For buyers or engineers sourcing high-performance fasteners, understanding the intricacies of thread pitch and design is not just academic—it directly impacts product reliability and customer satisfaction. As a manufacturer with extensive experience in precision fastening systems, we always recommend considering both the application environment and assembly process when choosing screw threads. Whether you’re working with lightweight electronics or structural components, the right thread design can help optimize both performance and cost.

In competitive B2B markets, every detail matters—and thread design is one of those hidden factors that separate generic fasteners from professional-grade solutions. If you're looking for expert guidance or premium stainless steel screws designed to meet the exacting demands of your industry, we’re here to help you choose with confidence and precision.

English

English русский

русский Deutsch

Deutsch عربى

عربى