+86 189 6101 2359

+86 133 6521 5663

+86 138 5268 6835

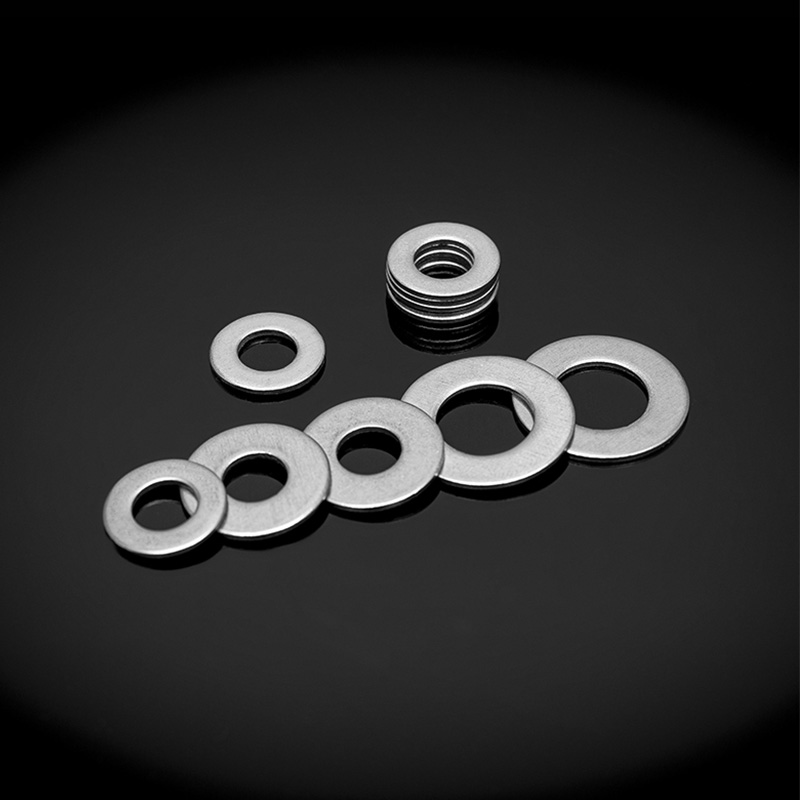

Stainless steel washers come in a variety of types, each designed to perform specific mechanical or structural functions in fastening systems. They are widely used in construction, machinery, automotive, marine, and industrial applications due to their corrosion resistance, strength, and reliability. Below is a detailed overview of the different types of stainless steel washers and their functions.

Content

Flat washers are the most common type of stainless steel washers. They are thin, round discs with a hole in the center that fits around a bolt or screw. Their primary purpose is to distribute the load of a threaded fastener evenly across the surface, preventing damage to the material being fastened and reducing the risk of loosening.

Spring washers, also known as lock washers, are designed to prevent nuts and bolts from loosening under vibration or dynamic loads. Their spring-like shape provides tension that maintains pressure on the fastener assembly.

Types include:

Applications: Automotive, electrical, and rotating machinery

Fender washers have a much larger outer diameter compared to standard flat washers. This wide surface area helps spread the load over a larger area, making them useful for protecting soft or thin materials such as sheet metal, plastic, or wood.

Countersunk washers, also known as cup washers, are used with countersunk screws. They provide a flush surface finish, allowing the screw head to sit neatly within the washer.

Sealing washers consist of a stainless steel outer ring combined with an inner rubber (neoprene, EPDM, or silicone) seal. They provide both mechanical strength and leak prevention by sealing around the fastener.

Tooth lock washers have serrated or toothed edges that bite into the mating surface to resist loosening.

Types include:

Applications: Electrical connections, vibration-prone machinery, and automotive systems

Dome washers have a curved shape and are used to cover and protect bolt heads or to provide a finished appearance. They can also accommodate slight misalignments between fastened surfaces.

Shoulder washers have an extended cylindrical portion that acts as an insulator or spacer. When made from stainless steel, they are used in high-strength assemblies where electrical insulation is not required but precise alignment or spacing is necessary.

Structural washers are thicker and stronger than standard flat washers, designed to handle heavy loads and high-pressure conditions.

Tab washers feature one or more tabs that can be bent against a bolt head or nut to lock it in place. They are used where vibration or movement could loosen fasteners.

These washers are used in pairs to compensate for misalignment between surfaces. The spherical washer has a convex face that matches the concave face of the conical washer, ensuring even load distribution despite angular misalignment.

Square washers have a square outer shape rather than a circular one. They provide a larger contact area and are commonly used in timber construction and channel or strut assemblies.

A type of spring washer with a conical shape, Belleville washers provide high load capacity and controlled deflection. They are often used in bolted joints requiring pre-load or thermal expansion compensation.

Stainless steel washers are available in many different types to suit specific mechanical and environmental requirements. From standard flat washers to advanced locking and sealing types, each plays a vital role in improving fastening performance, enhancing safety, and extending the service life of mechanical systems. Stainless steel grades such as 304 and 316 are commonly chosen for their corrosion resistance, strength, and versatility, making these washers suitable for both indoor and outdoor use in demanding conditions.

ThreadTolerance: 6gstandardDIN 13-15、DIN 13-12Rod diameter dd≤M20:A2-70、A4-70;M20<d≤M39:A2-50、A4-50;d≥M39:C3、C4;d<M39

See DetailsCopyright © Jiangsu Huajie Stainless Steel Products Co., Ltd. All Rights Reserved.

Stainless Steel Fasteners Manufacturers