+86 189 6101 2359

+86 133 6521 5663

+86 138 5268 6835

Content

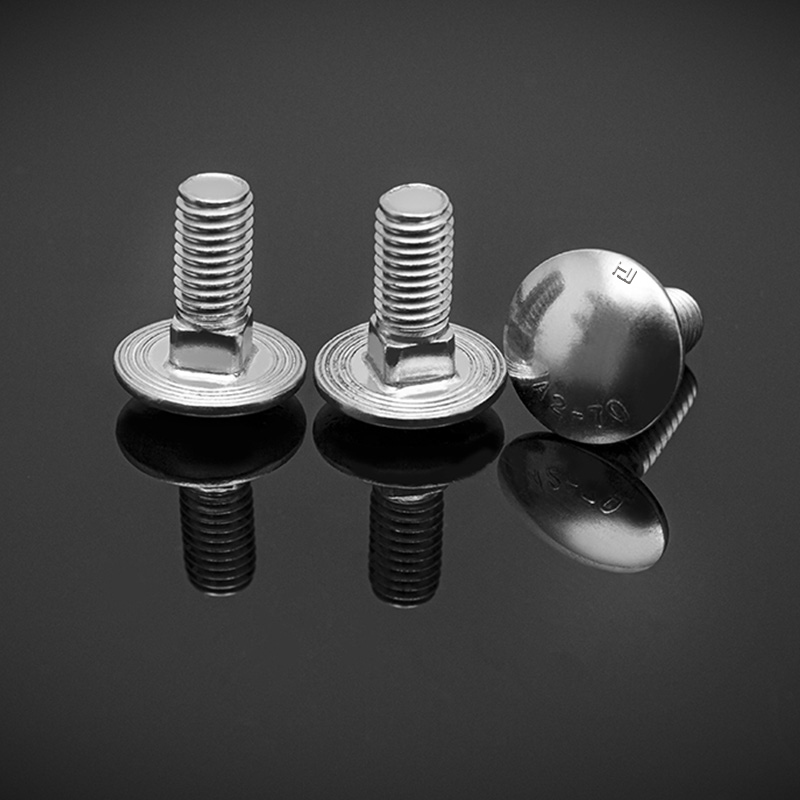

Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and an integrated square neck section beneath the head. This structure allows the bolt to resist rotation when installed into pre-punched square or tight-tolerance round holes. In structural and outdoor installations, this anti-rotation characteristic supports stable fastening when access to the bolt head is limited or when tightening is performed from the nut side only.

The mushroom head distributes clamping pressure over a wider surface area compared to standard hex heads. This reduces localized stress on softer materials such as wood, aluminum panels, or composite boards, which are commonly used in outdoor structures.

Stainless steel provides inherent resistance to corrosion caused by moisture, temperature variation, and airborne contaminants. In outdoor installations where fasteners are exposed to rain, humidity, or coastal atmospheres, stainless steel mushroom head square neck bolts maintain structural integrity without relying on surface coatings.

Different stainless steel grades are selected based on environmental exposure. Austenitic stainless steels are commonly used due to their balanced mechanical strength and corrosion resistance, making them suitable for long-term outdoor service.

The square neck section beneath the mushroom head is designed to embed into the mating material during installation. Once seated, it prevents the bolt from turning under load or vibration. This feature improves installation efficiency and contributes to joint stability in structures subject to wind loads or repeated mechanical stress.

In outdoor framing systems, fencing, and steel-to-wood connections, this anti-rotation behavior helps maintain consistent clamping force over time without frequent retightening.

Stainless steel mushroom head square neck bolts are selected for applications where both mechanical reliability and surface appearance matter. Their smooth head profile minimizes protrusions while supporting secure fastening.

These bolts support consistent performance in installations where access constraints and environmental exposure influence fastener selection.

The mushroom head geometry allows load to be spread evenly across the contact surface. This reduces the risk of material indentation and joint loosening, particularly in wood or thin metal sections used in outdoor structures.

Combined with proper washer and nut selection, stainless steel mushroom head square neck bolts help maintain joint alignment and reduce stress concentration under static and dynamic loads.

Accurate hole preparation is critical for effective square neck engagement. Holes should match the square neck dimensions closely to allow proper seating without damaging the surrounding material.

During installation, controlled torque application helps avoid galling, which can occur with stainless steel fasteners. Using compatible nuts and applying suitable lubrication improves installation consistency and long-term service performance.

| Fastener Type | Rotation Control | Surface Profile |

| Mushroom Head Square Neck Bolt | Built-in square neck | Low and smooth |

| Hex Head Bolt | Requires tool access | Raised head |

| Carriage Bolt | Limited square neck engagement | Rounded head |

For outdoor and structural installations that require stable fastening, corrosion resistance, and controlled surface appearance, stainless steel mushroom head square neck bolts provide a balanced solution. Their mechanical design and material properties support consistent performance across varying environmental conditions while simplifying installation and maintenance planning.

ThreadTolerance: 6gstandardDIN 13-15、DIN 13-12Rod diameter dd≤M20:A2-70、A4-70;M20<d≤M39:A2-50、A4-50;d≥M39:C3、C4;d<M39

See DetailsCopyright © Jiangsu Huajie Stainless Steel Products Co., Ltd. All Rights Reserved.

Stainless Steel Fasteners Manufacturers