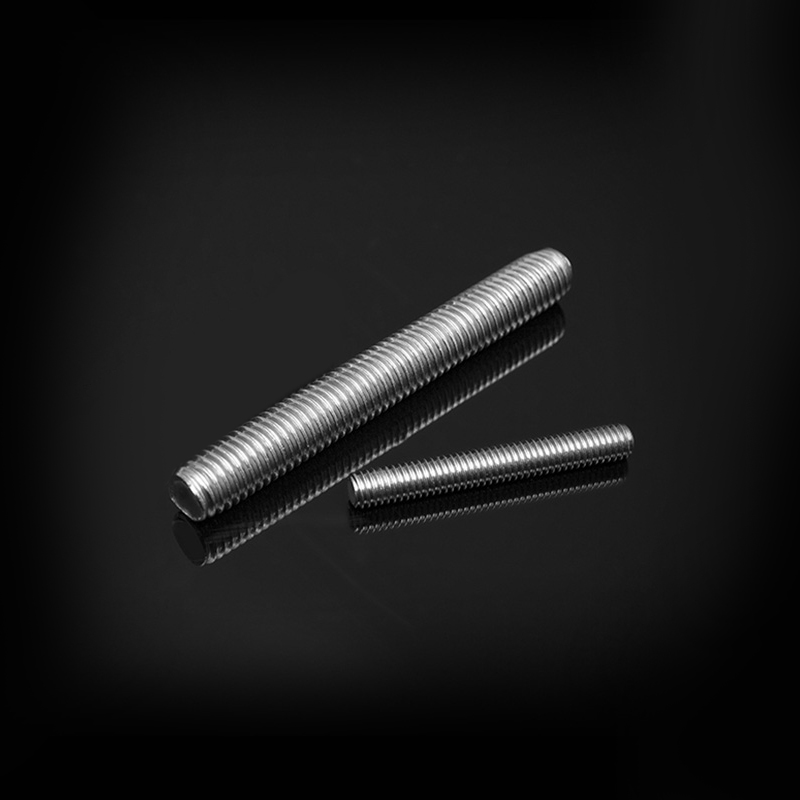

Understanding 316 Stainless Steel Threaded Rods 316 stainless steel threaded rods are highly versatile fasteners known for their exceptional corrosion resistanc...

READ MORE

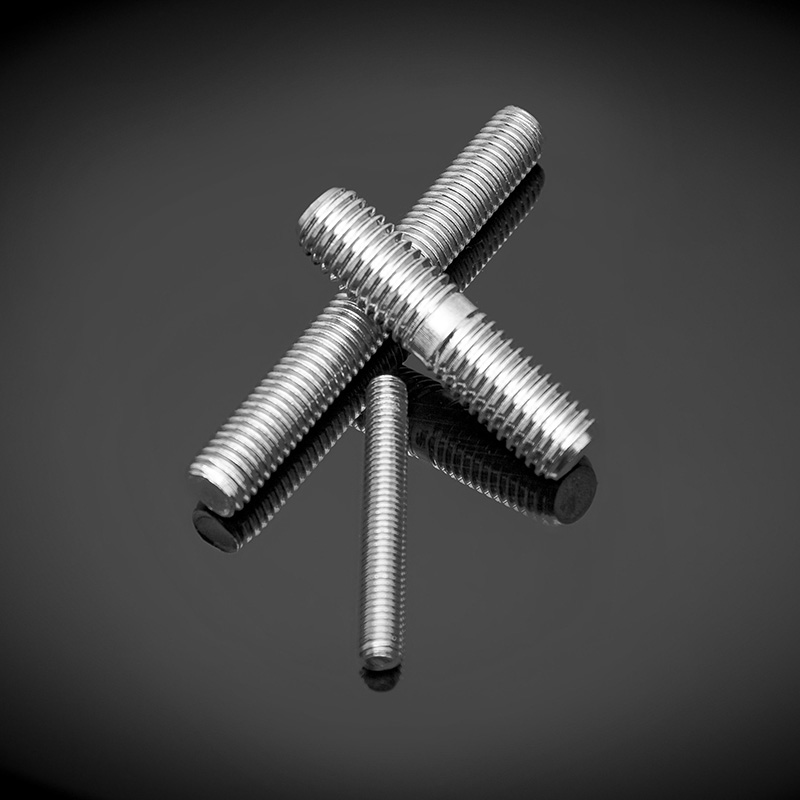

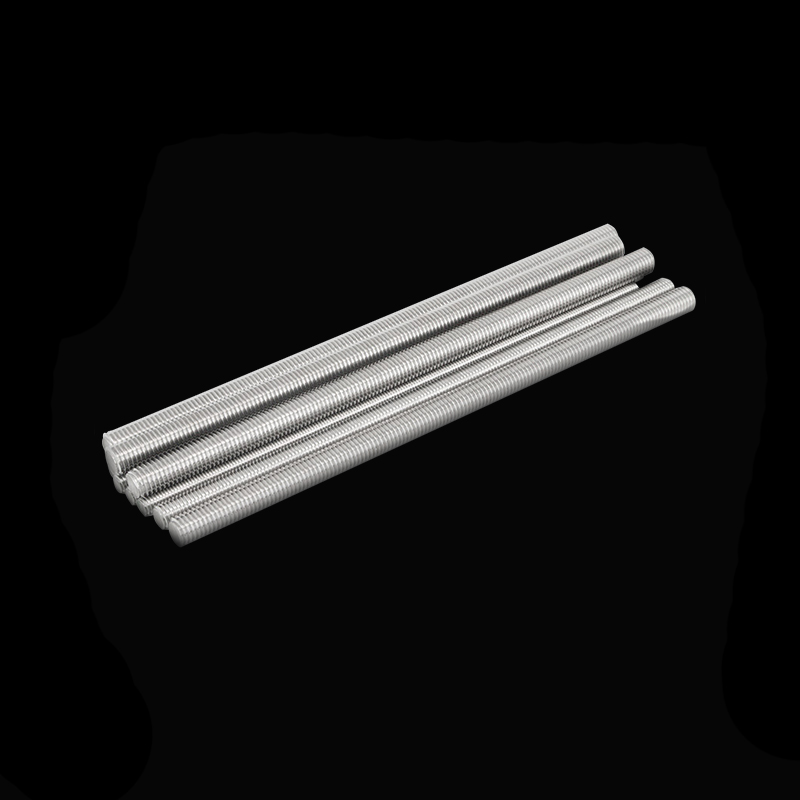

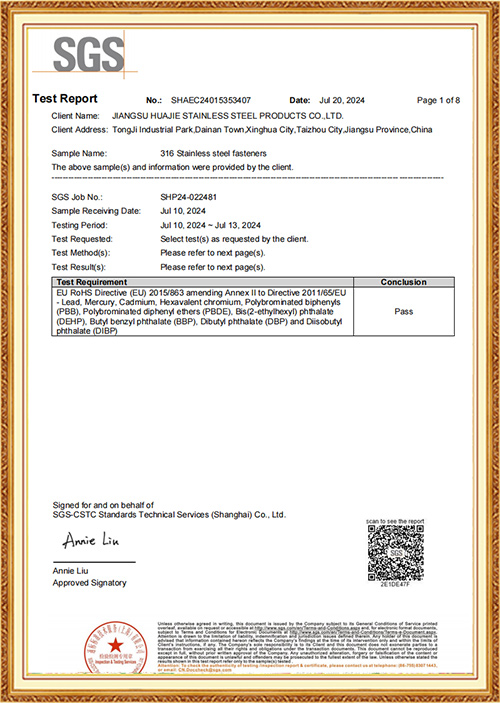

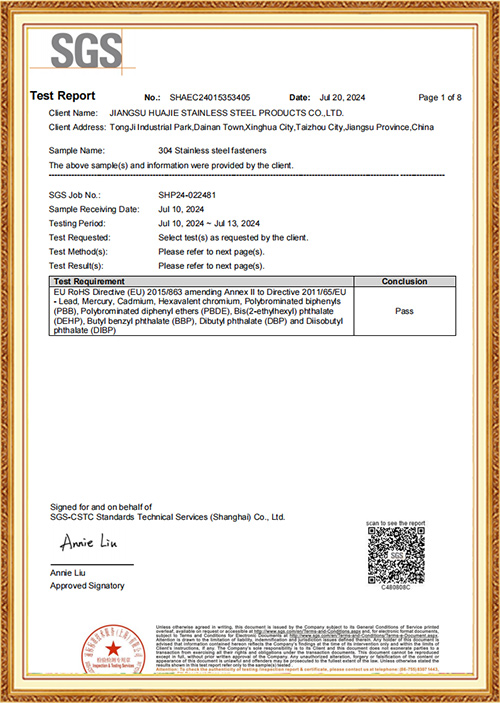

We are Wholesale Stainless Steel Studs Manufacturers and Stainless Steel Studs Factory in China, our company mainly produces stainless steel fasteners, The company has domestic and foreign advanced production and testing equipment, and product standards Cover GB/JIS/DIN/ANSI/ISO standards, The material includes 201/304/316L, etc. The products are widely used in high-speed rail, nuclear power, communications, new energy, mechanical equipment, petrochemical, military equipment, aerospace, and other fields.

-

-

Introduction to Hex Nuts Hex nuts are one of the most common fasteners used in machinery, construction, and various industrial applications. They are designed t...

READ MORE -

Structural Design Features of Mushroom Head Square Neck Bolts Stainless steel mushroom head square neck bolts are engineered with a low-profile rounded head and...

READ MORE -

Introduction to High-Strength Stainless Steel Screws High-strength stainless steel screws are essential fasteners for applications that demand durability, corro...

READ MORE

Understanding How Thermal Expansion Affects Stud Fasteners in High-Temperature Applications

In many industrial applications—especially in automotive engines, power generation equipment, and heavy machinery—stud fasteners are subject to repeated thermal cycling. When temperatures fluctuate, metals expand and contract at different rates. This seemingly simple phenomenon, thermal expansion, has a significant impact on the performance and reliability of fastened joints. For components joined by studs, particularly where disassembly is frequent or the surrounding materials differ in composition, not accounting for these effects can lead to joint failure, loosening, or even permanent deformation.

Studs, by design, offer stable clamping force and are commonly used in scenarios where dimensional changes must be tolerated while maintaining secure connections. However, when exposed to elevated or fluctuating temperatures, the expansion rates of the stud and the components it connects may not match. This mismatch can generate thermal stresses, which in turn affect preload—the initial tension applied to the fastener during installation. A decrease in preload can result in joint loosening under vibration or pressure, while excessive preload due to thermal mismatch might cause material fatigue or thread stripping.

This is where material selection plays a critical role. Stainless steel studs, for example, are widely chosen in high-temperature environments because of their excellent thermal stability, corrosion resistance, and predictable expansion characteristics. Austenitic grades like 304 and 316 offer low thermal conductivity and a relatively high coefficient of thermal expansion, which engineers must factor into joint design. While these properties provide benefits in corrosive or high-humidity environments, they also require precise torque application and may benefit from additional design considerations like thermal isolation or expansion joints.

In bolted assemblies where both the stud and the connected parts are of different materials—such as aluminum housings with stainless steel studs—the temperature-induced expansion gap becomes even more critical. Aluminum expands nearly twice as much as stainless steel under the same thermal load. This discrepancy can induce additional stress at the threads or change the load distribution across the joint. Manufacturers and designers must not only understand the coefficient of thermal expansion of each material but also model these interactions using finite element analysis or thermal simulation tools during the design phase.

From an operational standpoint, it’s also vital to monitor and maintain joints subjected to thermal cycles. Over time, even the best-designed assembly can experience relaxation of the joint due to creep or gradual loss of preload. For this reason, periodic inspection and re-torquing may be necessary, especially in systems exposed to thermal shock or continuous high-heat operation. Using precision fasteners such as custom-machined stainless steel stud bolts can help reduce variability and maintain more consistent joint behavior over time.

Customers in industries like automotive and energy frequently ask us how to improve performance in thermally demanding systems. Our recommendation is always the same: start with the right materials and understand the full thermal profile of the application. As a manufacturer and supplier with years of experience producing stainless steel studs for these exact conditions, we work closely with clients to tailor fastening solutions that are not only reliable but optimized for their specific operating environment.

In applications where thermal expansion is a concern, choosing the right stud isn’t just about size and strength—it's about understanding behavior under heat, material compatibility, and long-term performance. Stainless steel studs, when properly engineered and applied, provide a dependable solution that meets the complex demands of temperature-sensitive environments. Let’s help you get it right from the start.

English

English русский

русский Deutsch

Deutsch عربى

عربى