+86 189 6101 2359

+86 133 6521 5663

+86 138 5268 6835

Content

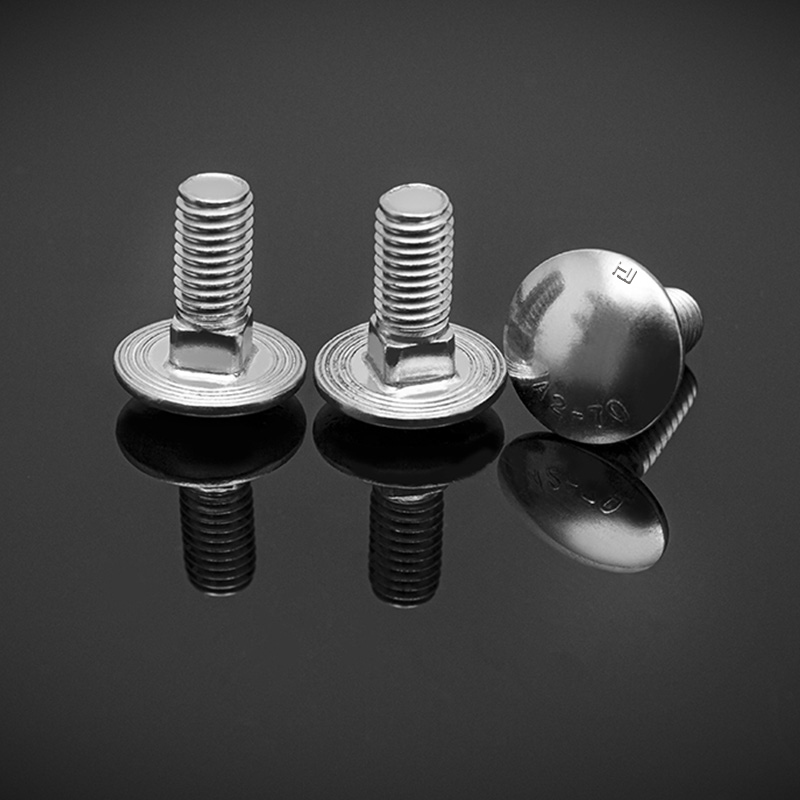

Stainless steel mushroom head square neck bolts are specialized fasteners designed to provide secure connections in applications where slippage must be prevented. The mushroom-shaped head offers a larger bearing surface, while the square neck below the head locks into place when inserted into a square hole, preventing rotation during assembly. These bolts are commonly used in wood, metal, and machinery components where stability and high-strength fastening are required.

The combination of a square neck and mushroom head allows these bolts to distribute load evenly while maintaining alignment in pre-drilled or pre-punched holes. This design enhances the bolt's resistance to loosening under vibration or torque stress.

Stainless steel is a preferred material for mushroom head square neck bolts due to its corrosion resistance, mechanical strength, and durability. These properties make stainless steel bolts suitable for both indoor and outdoor applications, including environments exposed to moisture, chemicals, or temperature fluctuations.

The unique mushroom head and square neck design provide several functional advantages. The wide, rounded head allows for even load distribution, reducing surface pressure on materials, while the square neck prevents rotation when tightening nuts or working in machinery with pre-cut square slots.

The mushroom head has a smooth, rounded surface that minimizes damage to contact surfaces. This feature is particularly valuable in applications such as conveyor systems, woodworking equipment, and furniture assembly, where surface integrity is critical.

The square neck fits into square holes or slots, effectively locking the bolt in place during installation. This prevents unwanted rotation, ensuring secure fastening even under dynamic forces or vibrations. The design also facilitates easier alignment and assembly in industrial processes.

These bolts are widely used in multiple sectors where strong, stable, and corrosion-resistant fasteners are required. Common applications include machinery, automotive components, furniture, and construction assemblies.

| Industry | Typical Application | Performance Requirement |

| Machinery | Equipment assembly and moving parts | Vibration resistance and load distribution |

| Furniture | Chair and table frame connections | Rotational locking and surface protection |

| Automotive | Chassis and body panel attachments | Corrosion resistance and high tensile strength |

Selecting the correct stainless steel mushroom head square neck bolt involves considering diameter, thread size, length, head diameter, and material grade. These specifications determine load capacity, corrosion resistance, and compatibility with the assembly environment.

Regular inspection of stainless steel mushroom head square neck bolts ensures long-term reliability. Check for surface corrosion, thread wear, and proper tightness in high-stress applications. Even with corrosion-resistant stainless steel, periodic maintenance prolongs service life and prevents unexpected loosening in critical assemblies.

Proper installation using compatible nuts or washers also contributes to performance stability, reducing the risk of material fatigue or assembly failure over time.

ThreadTolerance: 6gstandardDIN 13-15、DIN 13-12Rod diameter dd≤M20:A2-70、A4-70;M20<d≤M39:A2-50、A4-50;d≥M39:C3、C4;d<M39

See DetailsCopyright © Jiangsu Huajie Stainless Steel Products Co., Ltd. All Rights Reserved.

Stainless Steel Fasteners Manufacturers