+86 189 6101 2359

+86 133 6521 5663

+86 138 5268 6835

Content

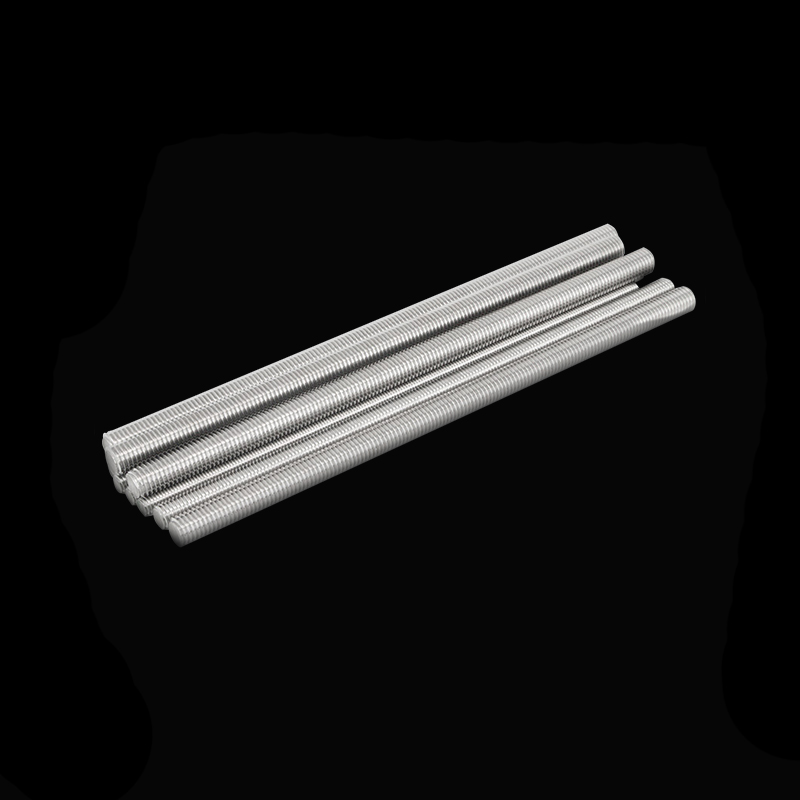

Stainless steel threaded rods are versatile fasteners used in a variety of construction, manufacturing, and industrial applications. They provide strong, reliable connections and resist corrosion, making them ideal for projects that require durability and longevity. Selecting the right rod involves understanding material grades, thread types, sizes, and environmental conditions.

Stainless steel threaded rods are available in multiple grades, each offering distinct characteristics. Common grades include 304, 316, and 321 stainless steel. Grade 304 provides general corrosion resistance and is suitable for indoor applications. Grade 316 is highly resistant to corrosion in harsh environments, such as marine or chemical settings. Grade 321 offers excellent heat resistance, making it ideal for high-temperature applications.

If the threaded rod will be exposed to moisture, chemicals, or saltwater, choosing a high-corrosion-resistance grade is essential. For outdoor and coastal projects, grade 316 is recommended to prevent rust and extend service life. In indoor, low-humidity environments, grade 304 is often sufficient and more cost-effective.

Threaded rods come in different thread types, including coarse (UNC), fine (UNF), and metric threads. Coarse threads are commonly used for general-purpose fastening, offering greater resistance to stripping and easier assembly. Fine threads provide higher tensile strength and better adjustment precision, suitable for critical load-bearing applications.

Ensure that the threaded rod’s pitch matches the corresponding nuts and washers. Using mismatched threads can compromise joint strength and cause failures. Metric rods should pair with metric nuts, while UNC/UNF rods require compatible imperial fasteners.

The diameter and length of the threaded rod must align with project requirements. Larger diameters provide higher tensile strength and are suitable for heavy-duty structural applications. Length should accommodate the material thickness being joined, with extra length for fastening and adjustments. Measuring accurately and considering load distribution is essential to prevent overloading and joint failure.

Consider the mechanical load that the rod must bear. Stainless steel threaded rods come in different strength classes, such as A2-70 or A4-80, indicating yield strength and tensile capacity. Selecting a rod that meets or exceeds project requirements ensures safety and structural integrity.

The installation environment plays a critical role in choosing a threaded rod. Exposure to chemicals, high humidity, or extreme temperatures demands higher corrosion-resistant grades. Indoor construction projects with minimal exposure may use standard rods to reduce costs. Evaluating vibration, stress, and movement in the application is also important to prevent loosening or fatigue.

Surface finish affects both appearance and performance. Common finishes include plain, bright, or passivated. Passivated rods have enhanced corrosion resistance, suitable for outdoor or chemical environments. Bright or polished finishes improve aesthetics for visible applications.

| Grade | Key Features | Best Applications | Typical Strength Class |

|---|---|---|---|

| 304 | General corrosion resistance, cost-effective | Indoor, dry environments | A2-70 |

| 316 | High corrosion resistance, suitable for harsh conditions | Marine, chemical, outdoor projects | A4-80 |

| 321 | Excellent heat resistance, corrosion-resistant | High-temperature or industrial applications | A4-70 |

Selecting the right stainless steel threaded rod requires evaluating material grade, thread type, diameter, length, and environmental conditions. By understanding these factors, you can ensure reliable performance, corrosion resistance, and structural integrity for your project. Careful selection enhances safety and durability while optimizing cost-effectiveness for a wide range of industrial and construction applications.

ThreadTolerance: 6gstandardDIN 13-15、DIN 13-12Rod diameter dd≤M20:A2-70、A4-70;M20<d≤M39:A2-50、A4-50;d≥M39:C3、C4;d<M39

See DetailsCopyright © Jiangsu Huajie Stainless Steel Products Co., Ltd. All Rights Reserved.

Stainless Steel Fasteners Manufacturers