+86 189 6101 2359

+86 133 6521 5663

+86 138 5268 6835

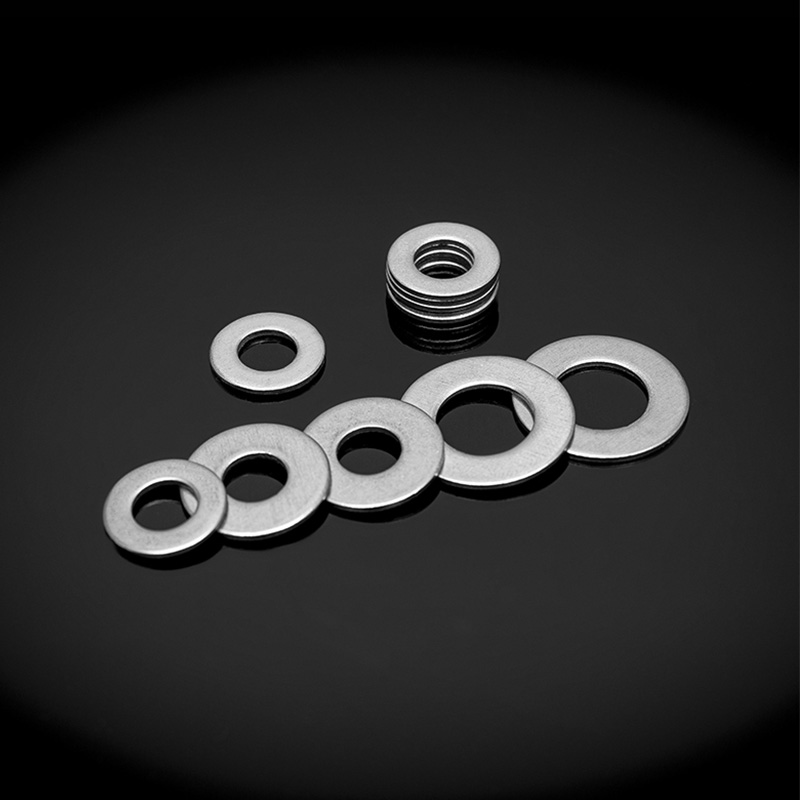

Stainless steel flat washers are simple yet crucial components in bolted assemblies. Their primary function is to distribute the load from a fastener over a larger surface area, preventing damage to the material being fastened. Made from corrosion-resistant stainless steel, these washers provide long-lasting durability in harsh environments, including industrial, marine, and outdoor applications. Their strength ensures that even under high clamping forces, the washer maintains integrity without deforming excessively.

Content

When a bolt or screw is tightened, the force is concentrated on the small area of the fastener head. This localized pressure can cause indentations, scratches, or cracking of softer materials such as wood, plastic, or thin metal sheets. A stainless steel flat washer spreads the load across a wider area, reducing stress on the surface and ensuring a more even distribution of clamping forces. By doing so, it prevents material deformation and maintains the structural integrity of the assembly.

The effectiveness of load distribution depends on factors such as washer thickness, diameter, and material grade. Thicker washers or those with larger outer diameters provide better load-spreading capability, especially in heavy-duty applications where high torque is applied. Using stainless steel adds additional benefits, as the material resists corrosion, maintaining consistent performance over time.

Beyond load distribution, stainless steel flat washers serve as a protective barrier between the fastener and the surface. Direct contact between a fastener head and a material can create scratches, dents, or other surface imperfections. By placing a washer between them, the contact is evenly distributed, preventing concentrated pressure points that could compromise the appearance or function of the material.

In applications where aesthetic integrity is important, such as furniture assembly or architectural structures, stainless steel washers ensure that fasteners do not mar the surface. They are particularly effective on softer surfaces like aluminum, composite panels, or coated metals, where direct contact with a bolt could lead to permanent damage.

Choosing the appropriate washer is essential for achieving optimal load distribution and surface protection. Consider the following factors:

| Washer Type | Primary Benefit | Best Use Case |

| Standard Flat Washer | Even load distribution | General mechanical assemblies |

| Thick Flat Washer | Handles high torque loads | Heavy-duty industrial applications |

| Large Diameter Washer | Maximizes load spreading | Soft or delicate materials |

| Specialty Coated Washer | Corrosion and surface protection | Marine or chemical environments |

Stainless steel flat washers play a critical role in bolted assemblies by distributing clamping forces evenly and preventing surface damage. Their corrosion resistance, durability, and ability to handle high torque make them indispensable in industrial, marine, and structural applications. Selecting the right washer based on material, dimensions, and application environment ensures long-term assembly integrity, reduces maintenance, and protects both functional and aesthetic aspects of the surfaces being fastened.

By understanding the principles of load distribution and surface protection, engineers and installers can optimize the performance of fasteners, prevent material damage, and enhance the safety and reliability of mechanical structures.

ThreadTolerance: 6gstandardDIN 13-15、DIN 13-12Rod diameter dd≤M20:A2-70、A4-70;M20<d≤M39:A2-50、A4-50;d≥M39:C3、C4;d<M39

See DetailsCopyright © Jiangsu Huajie Stainless Steel Products Co., Ltd. All Rights Reserved.

Stainless Steel Fasteners Manufacturers