By precisely controlling every step in the manufacturing process, we can ensure the consistency and reliability of product quality.

Technical Advantages

-

01

-

02

Meet Diverse Demands

With flexible manufacturing processes, we can produce fasteners of various specifications and shapes, offering customized products and services to meet the needs of different customers.

-

03

Enhance Production Efficiency

By automating and optimizing the process flow, we effectively increase production efficiency and ensure, or even shorten, delivery times.

-

04

Promote Innovation and R&D

By continuously exploring and applying new manufacturing technologies and materials, we can drive innovation research, and development within the company.

Production Process

-

Material Selection

Choosing the right stainless steel material is the 1st step in manufacturing high-quality fasteners. Commonly used stainless steel materials include 304, 316, etc. -

Cold Heading

It is a primary process in the manufacturing of fasteners, where stainless steel wire or bar stock is formed into the desired shape at room temperature using a cold heading machine. -

Wire drawing/drawing

Stainless steel fasteners may undergo Wire drawing processes during their manufacturing to improve the mechanical properties and corrosion resistance of the material. -

Threading

The thread is a critical part of a fastener and can be processed through methods such as turning, rolling, or tapping. -

Surface Finishing

In order to enhance corrosion resistance and aesthetics, stainless steel fasteners may require surface treatments such as polishing, passivation, plating, or coating. -

Quality Control

Throughout the entire manufacturing process, strict quality control is essential, including dimensional inspection, material testing, and thread inspection. -

Cleaning and Drying

During the manufacturing process, fasteners need to be cleaned and dried to remove oil stains, dust, and metal shavings generated during machining. -

Customized Packaging

To protect fasteners from damage during transportation and storage, proper packaging is required, and it can also be customized according to customer needs. -

Non-destructive Testing

Testing and performance testing are carried out in parallel to ensure the internal quality of the fasteners and to meet specific performance requirements.

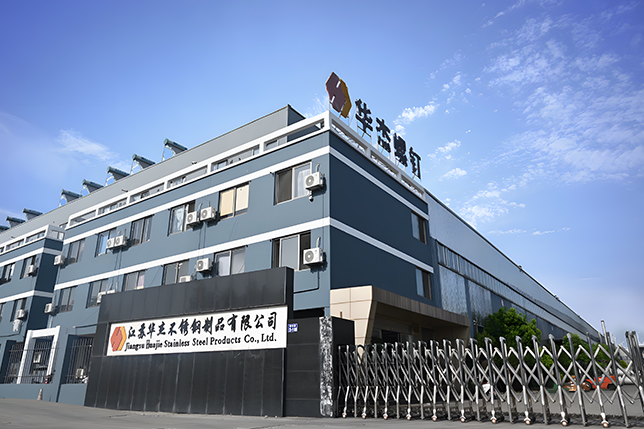

Professional Stainless Steel Fastener Manufacturer

Jiangsu Huajie Stainless Steel Products Co., Ltd. was founded on 2003, mainly produces stainless steel hexagonal bolts, stainless steel hexagonal bolts, stainless steel nuts, stainless steel threaded rods and other products. The raw materials are 201, 304, 316L series high-quality wire.

Covering an area of 13,000 square meters ,annual production capacity of 60,000 tons, through 20 years of development, for now HuaJie is a competitive stainless steel fastener manufacturers in China.

Complete Industrial Chain and Process

After years of development and improvement, the company has formed a one-stop industrial chain service from raw materials---production---quality inspection---packaging and logistics---after-sales service.

The stainless steel fastener industry chain is a complex and highly specialized system that covers multiple links from raw material production to final product delivery. Each link is closely linked to ensure that product quality and performance meet market demand.

Unique Storage Conditions

Bulk orders allow manufacturers to secure pricing and availability for a predetermined quantity of fasteners over an extended period. This strategic procurement method provides price stability, simplifies the purchasing process, and ensures consistent supply throughout the project's lifecycle. It also enables buyers to negotiate favorable terms and conditions with suppliers, which helps in cost reduction and budget management.

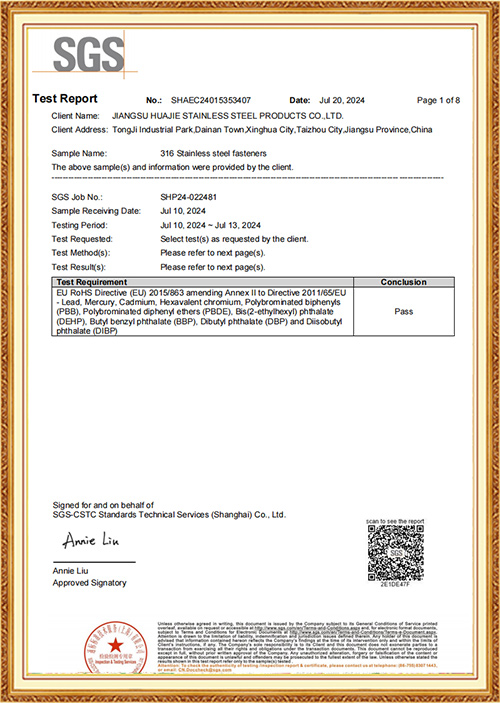

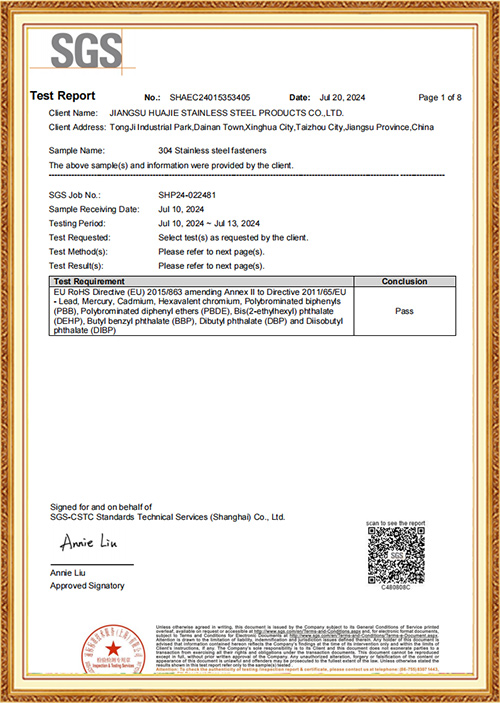

Performance Testing

We maintain an unwavering commitment to product quality and safety.

-

One-stop Intelligent Transportation Lighting Solution Provider More Than 10+ Years

--Technical Consulting

--Product Selection

--Application Guide

--Technical Training

--After-Sales Maintenance

English

English русский

русский Deutsch

Deutsch عربى

عربى